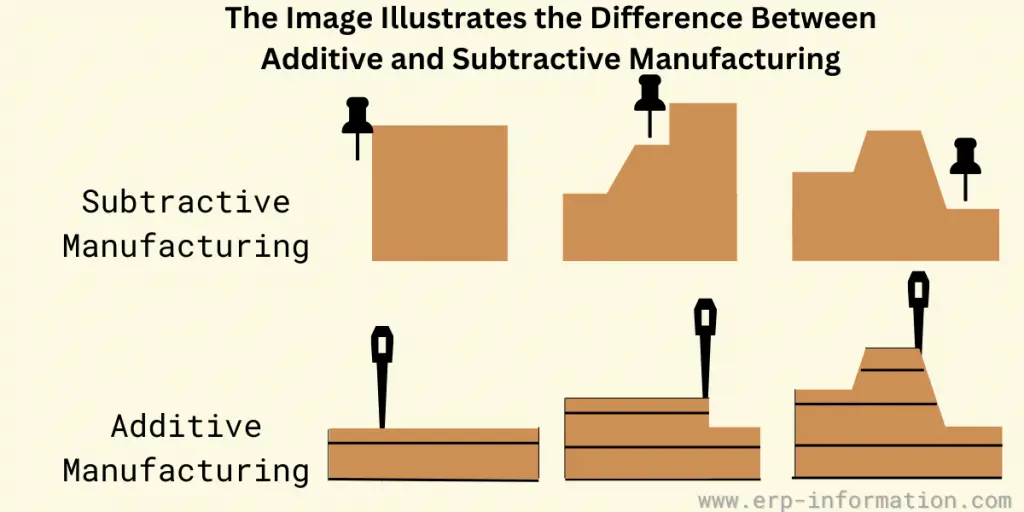

Additive manufacturing is also known as 3D printing. That means adding materials layer by layer to create a three-dimensional object.

On the other hand, subtractive manufacturing is the traditional way of making things by removing materials from a larger piece to create the desired shape.

The article will discuss additive and subtractive manufacturing. Here’s a quick rundown of additive vs subtractive manufacturing.

Evaluate 3D print time using our online 3D Print Time Calculator

What is Additive Manufacturing?

Additive manufacturing is making a three-dimensional object from a digital model by adding successive layers of material.

What is Subtractive Manufacturing?

Subtractive manufacturing is a process in which material is removed from a workpiece to create the desired shape.

Additive Manufacturing vs Subtractive Manufacturing

| Additive Manufacturing | Subtractive Manufacturing |

| Builds an object by adding layers of material. | Removes material from a larger piece to create an object. |

| This process includes digital manufacturing, 3D printing, and additive fabrication. | This process includes traditional machining, CNC machining, or manual removal. |

| Creates prototypes or product models first by using computers and 3D printing equipment. | It turns, drills, and other machining processes using computers and robotics. |

| It is a slow process. | It is a fast process. |

| You must do post-printing to surface finish by sanding or blowing because layering makes a rough surface. | Surface finishing can be done by machining like smoothing, stepping, etc. |

| It can be used with limited materials like plastics and metals. | Suitable for all types of materials like metal, plastic, wood, composites, and glasses. |

| It is best suited for small items. | It is best suited for large items |

| A machine operator is unnecessary in this process because the software will take care of the 3D printer. | Here, the machine operator required to monitor the CNC machine. |

| Less expensive | More expensive |

| Suitable for small-batch production | Suitable for large-scale production |

| The finished product will have a weak structure | The finished product will have a strong structure. |

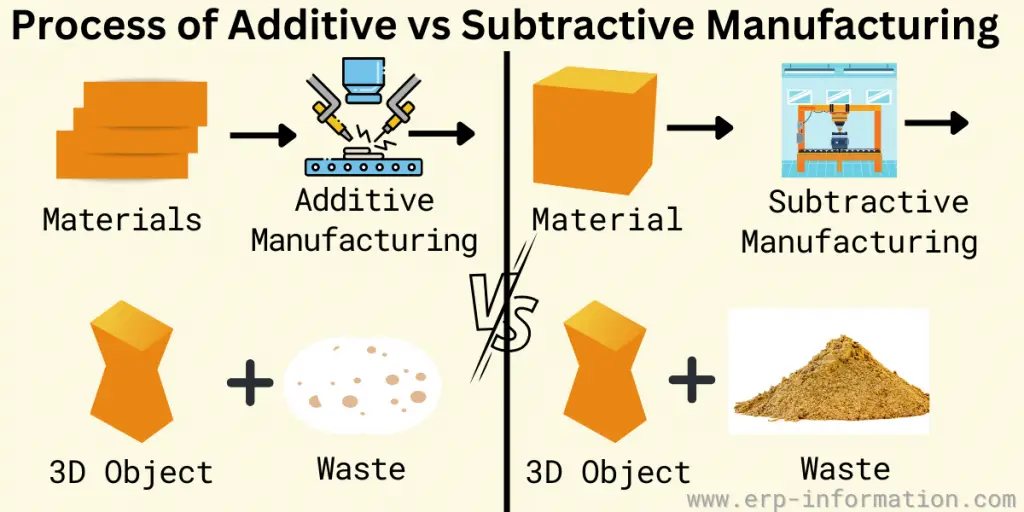

Additive vs Subtractive Manufacturing Process

Now that you know the difference between additive and subtractive manufacturing, you can decide which manufacturing method is suitable for your next project.

Additive manufacturing is more versatile because it can be used to create complex shapes that would be impossible to make with subtractive manufacturing.

It’s also more efficient since there’s no need to remove excess material.

So, which one is better? It depends on your needs. If you need to create a complex object quickly and cheaply, additive manufacturing is the way.

On the other hand, if you need a specific object, subtractive manufacturing is the better option.

Pros and Cons of Additive and Subtractive Manufacturing

Pros of Additive Manufacturing

- Complex Geometries: AM excels in producing intricate and complex geometries that would be challenging with subtractive manufacturing (SM).

- Prototyping: AM is a game-changer for rapid prototyping and iterative design phases, allowing for quick and cost-effective adjustments to product designs.

- Low-Volume Customization: When custom, low-volume production is needed, AM offers unparalleled flexibility without the need for costly tooling changes.

- Lightweight Structures: AM is ideal for creating lightweight yet structurally robust components using lattice structures and minimizing material waste.

- Reduced Material Waste: Compared to SM, AM generates minimal material waste as it adds material layer by layer, making it a sustainable and environmentally friendly choice.

Cons of Additive Manufacturing

- It can be slow and expensive compared to subtractive manufacturing.

- It often results in a poorer surface finish than subtractive manufacturing.

Pros of Subtractive Manufacturing

- High Precision: SM is the go-to method for high-precision parts, achieving tight tolerances and superior surface finishes.

- Mass Production: When large quantities of identical parts are required, SM is more time-efficient and cost-effective, especially for materials like metals and ceramics.

- Post-Processing: SM is preferred for parts that require specific surface treatments or secondary machining processes, providing a smooth starting point.

- Mature Materials: SM is versatile and well-established when working with a wide range of materials, including metals, ceramics, and composites.

Cons of Subtractive Manufacturing

- It is limited to objects that can be created by removing material from a more significant piece.

- Produces waste materials as machining removes layers from the block of raw material.

- It requires specialized equipment and skills, which can be costly.

Additive vs Subtractive Manufacturing Cost

Tooling and machinery cost

Additive Manufacturing

- It is the cheaper option

- That is because additive manufacturing machines are often smaller and simpler than subtractive machines, requiring less capital investment.

- Additive manufacturing doesn’t require expensive toolings like milling and drilling machines.

- That makes additive manufacturing a more cost-effective option for small-scale production.

Subtractive Manufacturing

- It is generally more expensive to set up.

- That is because subtractive machines are usually larger and more complex than additive machines.

- Tooling costs can add up quickly with subtractive manufacturing. For example, a new mold must be created each time a new product is made.

- It can become costly, especially for small businesses.

Material cost

The material cost of additive manufacturing is significantly higher than that of subtractive manufacturing. That is because additive manufacturing requires more material to produce a part, whereas subtractive manufacturing can reuse scrap material.

However, the difference in material cost is offset by the greater efficiency of additive manufacturing, which reduces the amount of waste produced.

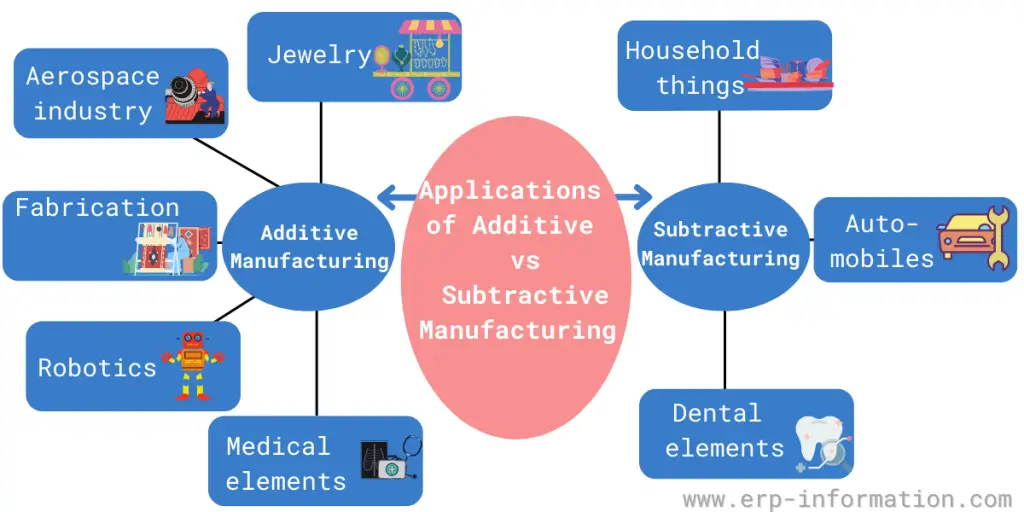

Applications of Additive vs Subtractive Manufacturing

- Additive manufacturing is used in jewelry, aerospace manufacturing, model fabrication, robotics, and medical elements.

- Subtractive manufacturing makes household things, automobiles, and dental elements.

FAQs

What are some examples of Additive Manufacturing?

Common examples of additive manufacturing include 3D printing, laser sintering, and stereolithography.

What are some examples of Subtractive Manufacturing?

Some common examples of subtractive manufacturing include milling, turning, and drilling.

Why additive manufacturing is better than subtractive manufacturing?

Additive and subtractive manufacturing are two approaches to producing parts and products. Additive manufacturing creates final products by adding material layer by layer, while subtractive manufacturing involves removing material from a larger piece to make the final product.

Here are some reasons why additive manufacturing is sometimes considered better than subtractive manufacturing:

1. Less Waste: Additive manufacturing can create parts more efficiently and with less waste since only the required amount of material is used.

2. More Design Freedom: Additive manufacturing allows for more design freedom since complex shapes can be created that are not easy to produce with subtractive manufacturing. Sometimes, it is impossible with subtractive manufacturing.

3. Reduced Production Time: Additive manufacturing can be faster than subtractive manufacturing since parts can be produced more quickly and without needing as many separate operations.

4. Lower Start-Up Costs: Additive manufacturing requires less investment in tooling and other specialized equipment, making it easier and less expensive to start small-scale production.

5. Customized Production: Additive manufacturing allows for more customized production, making it better suited for producing small batches or customized products.

Amongst Additive and Subtractive manufacturing processes which of the two is environmentally friendly?

Owing to its lower material wastage compared to other manufacturing processes. Additive manufacturing proves to be more environmentally friendly than subtractive manufacturing.

What is hybrid manufacturing?

Hybrid manufacturing is a production approach that combines the strengths of both Additive Manufacturing (AM) and Subtractive Manufacturing (SM) processes.

It involves creating parts or components through AM to achieve complex geometries and then using SM to refine the surfaces, add fine details, or meet precise tolerances.

An example of hybrid manufacturing is the aerospace industry, where AM is used to produce intricate and lightweight components, followed by SM for precision machining and surface finishing to meet strict aerospace standards for performance and safety.

This approach optimizes the production of high-quality, custom aerospace parts.

In which situations is hybrid manufacturing, a combination of Additive and Subtractive Manufacturing, a practical choice?

Hybrid manufacturing is employed when a part requires the benefits of both methods. For instance, you might use AM to create a complex shape and then apply SM for precise finishing or to add threaded holes.

Conclusion

Additive and subtractive manufacturing are two very different ways of creating objects. Additive manufacturing, often referred to as 3D printing, involves adding layers of material on top of each other until the desired object is created.

Subtractive manufacturing, which includes processes such as machining and milling, starts with a larger piece of material and removes parts from it until the desired object is left behind.

This blog post explored additive vs subtractive manufacturing with examples of each type and discussed the pros and cons of each.