Raw materials play a crucial role in the manufacturing industry, serving as the fundamental building blocks for production processes.

Without them, the entire manufacturing ecosystem would crumble, highlighting their immense significance in driving productivity and ensuring the seamless flow of operations.

The seamless flow of operations relies on a crucial element known as the Bill of Materials (BOM).

This essential document meticulously outlines the components, quantities, and specifications required for manufacturing various products.

With an accurate BOM in place, companies can efficiently manage their inventory, ensure timely procurement of materials, and maintain a smooth and uninterrupted production cycle.

In this article, you will get complete and well-researched information about BOM. The article will discuss the meaning, types, examples, future, and management software of the bill of materials. It will also provide key terms associated with it.

What is a Bill of Materials?

A bill of materials primarily consists of raw materials, parts, components, assemblies, sub-assemblies, and other items required to manufacture, repair, or reconstruct an item.

The number of materials needed, the time consumed, and the necessary amount of labor in each subpart to be arranged accordingly are available.

The Bill of Materials definition generally says it is like a communication card between the planning and designing units and the manufacturing unit. Hence, it might also be a production recipe if required.

Multiple-level of it provides more essential details and information than single-level.

Bill of Materials Example

While building a racing bike, the builder will need various tools to make the bike from scratch.

Items like wheels, brakes, seats, handles, a pulley, a chain, plenty of small nuts, and screws, along with various other things.

A BOM for building a racing bike would also contain the quantities required for each item.

The type might also contain the steps to build the bike and the labor and time consumed by each stage.

The BOM is the blueprint for building, rebuilding, or repairing any item or product of interest. All the workers involved in the manufacturing and post-production processes must also be aware of the BOM. It connects the various units required for the final product to be ready.

In this case, the final product is the racing bike. The bike preparation assembles all cycle parts and the seat, handles, and brakes.

One missing item might stop the product from being viable, such as the cycle here might not work without the chain, might not even start without the wheels, and might not stop without the brakes.

It is essential to know how to make a bill of materials to create the structure for any manufacturing unit.

Bill of Materials Inventory Management

It is crucial for inventory management when finished products are built from components.

Typically, it is used for production planning in manufacturing. However, it is essential when multiple parts are required to make finished products and services.

It is crucial for the inventory management department because it allows them to forecast, plan, and order exact quantities of each part required to make final goods that avoid stockouts and production delays.

How does the Bill of Materials Help?

It is used in businesses mainly as the roadmap to functioning a finished product.

- Plans the purchasing with the help of automation

- Keeps a tab on the total purchases of all the materials required sequentially, helping a cost-effective plan to materialize.

- Maintains proper records and plans materials requirements.

- It also helps keep a tab on inventory control, thus preventing and reducing waste.

- Bills of materials designed for any product pave a path ahead and allow scope for rising productivity and yield, thus resulting in more profit.

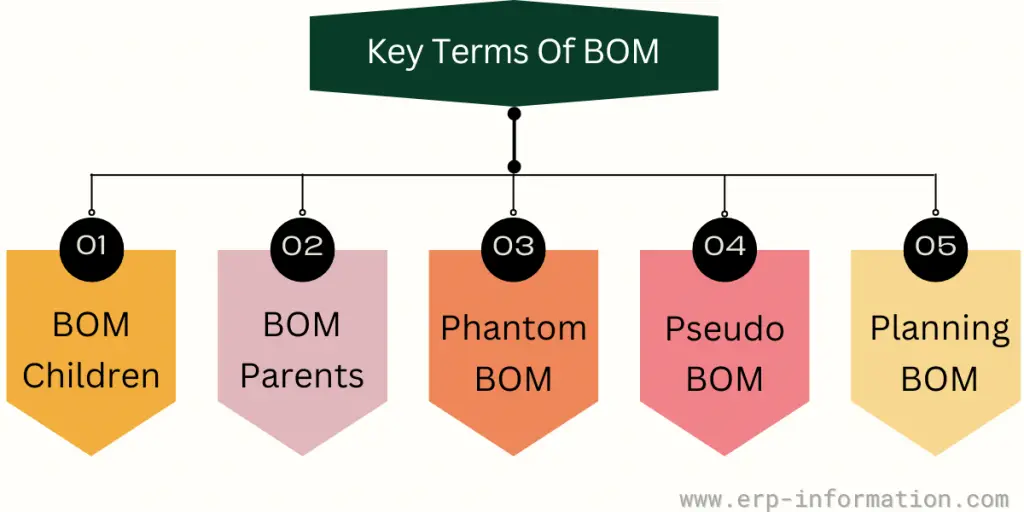

Key terms associated with the Bill of Materials

The inventory of terms related to it is essential to managing BOMs. Therefore, it is necessary to understand this correctly.

BOM Children

These subparts can be assemblies, sub-assemblies, or BOM hierarchy parts. They are usually raw materials that are required for the final product.

For example, if a company manufactures a car, the children would be the parts that make up the car, such as the engine, wheels, and body.

The company would then assemble these parts to create the final product. BOM children are an essential part of the manufacturing process, as they help ensure all the necessary components are available for the final product.

BOM Parents

The central element in a hierarchical BOM is the component present at the top. Mentioned product descriptions and price for the parent from which branching of raw materials has been generated to give a hierarchical structure.

Phantom BOM

An item that is physically built but not stocked or created into an inventory is an intermediate step. Instead, it gets absorbed in another process known as a Phantom item.

These are easily accounted for because only a demand for the following product justifies the existence of a phantom item.

Pseudo BOM

It refers to a more flexible form that can be readjusted more suitably to meet the needs of primarily related and interchangeable groups with common attributes.

In other words, it is a system that allows for easier changes and substitutions to be made in response to the specific requirements of a project.

This system can benefit industries where products are frequently updated or replaced, allowing quicker and more efficient changes. Overall, it can help improve manufacturing processes’ efficiency and flexibility.

Planning BOM

It is also no different from the regular ones. It comprises a summary of the items required to produce a final thing.

It also plans on unforeseen demands that might arise over time.

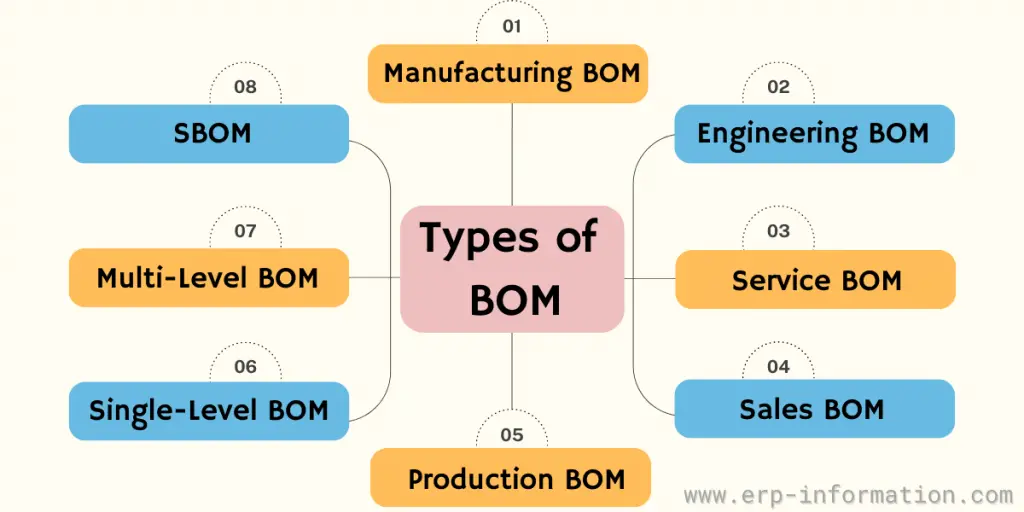

Types of Bill of Materials

Various types are used in manufacturing units, depending on the nature of the finished product.

A BOM is hierarchical, with the finished goods on the top and print codes and manufacturing dates.

The following line consists of broad aspects of raw materials required. Separate BOMs have different designs and structures.

Manufacturing Bill of Materials (mBOM)

It is the most common type for a manufacturing company as it makes the functioning of a manufacturing unit smoother and more coordinated.

It displays all the assemblies and sub-assemblies of parts required to manufacture a final product.

A manufacturing unit works with other integrated teams required to function several processing events before manufacturing.

Hence, a reliable road map with all the information is provided along with the quantities. These quantities make it easier to order all the parts.

This also makes it easier to achieve a cost-effective strategy by negotiating the best possible price from the vendor.

Engineering BOM (eBOM)

It is prepared during the design phase of any product. A computer-based design is ready, along with detailed descriptions of products and parts required under their relationship with the final product, as depicted in the drawing.

A company can have more than one of them as there might be different angles to a product.

For example, there might be a safety and maintenance angle to a product and productivity and yield might be considered another.

All the product’s functioning ideas must be considered when a design is prepared using Electronic Design Automation (EDA) tools.

Questions like how does it function? How does it cope with malfunctions? How to make a cost-effective design? Need to be answered.

Service BOM

It consists of lists of items required by a service person for installing, repairing, or restocking products and information needed by the technician for performing their services.

These services could be at the site of business or manufacturing. In addition, the company maintains it, which is essential for the proper functioning of the product.

Sales BOM

It comprises items that have been put on sale. Items for selling and stock are listed with adequate product descriptions alongside every item.

The finished product and every part must have the final product functioning properly. In the case of a Sales Bill of materials, the critical fact is that all items listed here are not inventory, unlike any other.

Production Bill of materials

It consists of items, product descriptions, and prices.

The items listed here are assemblies and sub-assemblies that ultimately will be converted into a finished product after the production process.

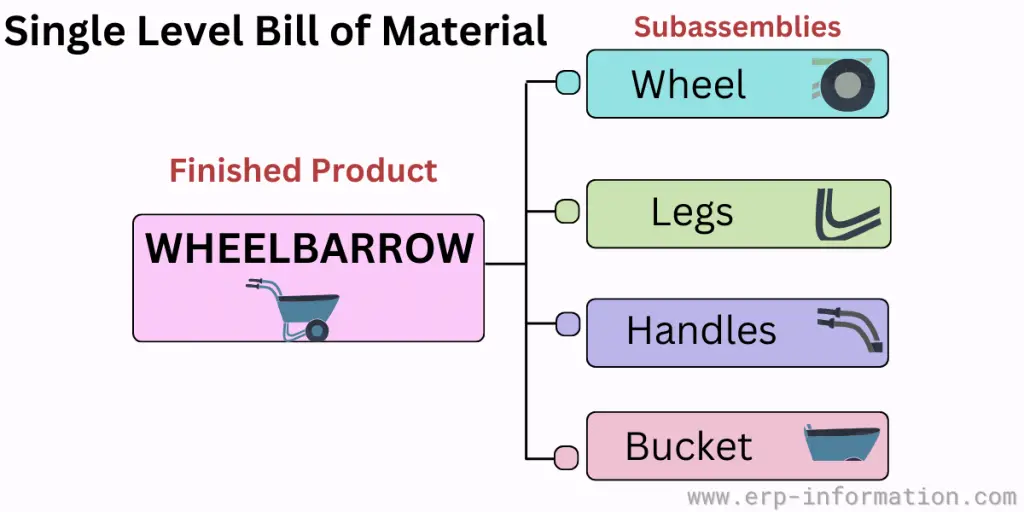

Single-level Bill of materials

This is the most simple and least complicated. The Children or assemblies and materials required for processing are only up to one level.

All the parts listed under the parent must produce the final product. Most small to medium businesses work with single-level.

Typically all the components needed are listed here as a broad category. However, it can add more levels based on the increasing complexity of the product design.

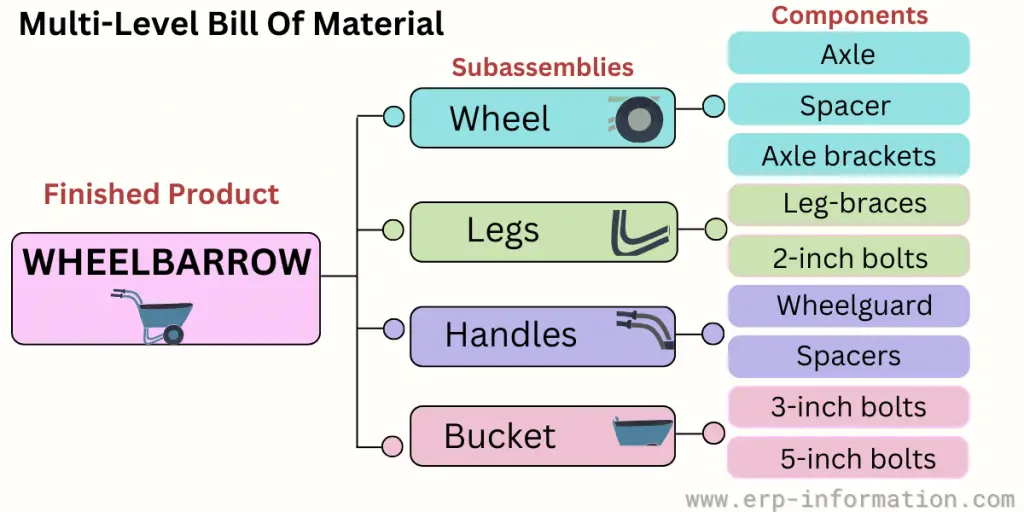

Multi-level BOM

It is used in a more complicated product design where more parts and sub-assemblies are required. In this case, more than one level of children is listed under the final product.

It results in a more detailed and well-structured product design with specific descriptions for every aspect of the product.

SBOM

It refers to the list of software components and the respective versions used in building a software system.

The purpose is to provide a common understanding between all stakeholders about the contents and versions of software components used in the build.

More about SBOM

How to create a Bill of materials?

The first step to creating it is knowing your business inside out. Finding out all there is essential. Next, you must ask questions like, what am I manufacturing? How will I manage it?

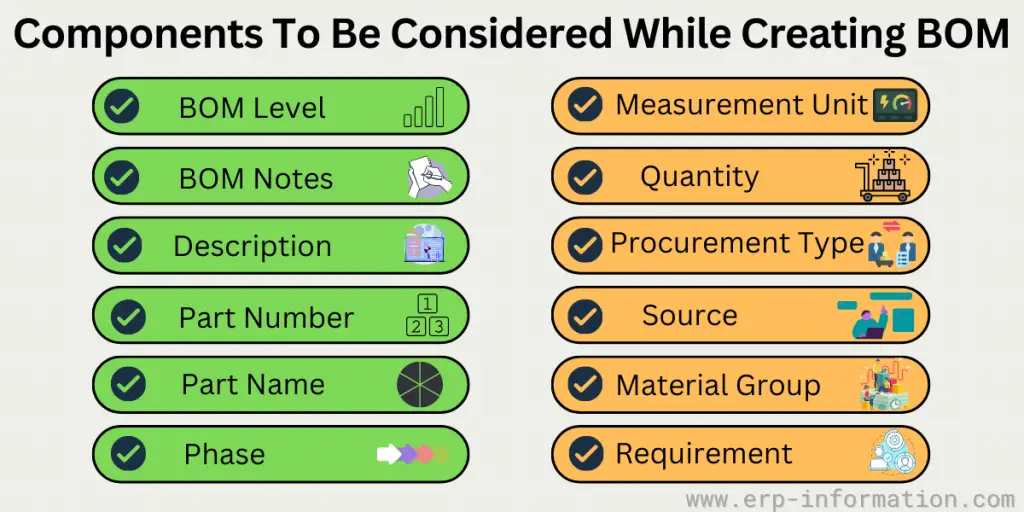

What are the components to be considered while creating a bill of materials?

You must consider several components to create an accurate and complete bill of materials. First, could you identify the level at which it will be made?

This will determine the level of detail required for each part. Minor details may be needed if it is for a lower-level product.

Next, each part should be provided, including the part number, name, and measurement unit. The quantity of each piece needed should also be specified as the procurement type and phase.

This will give the manufacturer a clear idea of what is required to produce the product.

Finally, any special requirements should be noted so that we can avoid delays or errors in the manufacturing process.

For instance, if a specific color is required, this should be indicated on the Bill of Materials. Considering all these factors makes it possible to create a bill of materials that accurately reflects the project’s needs.

BOM level

This ranking is given to each part or assembly within the broader BOM. It makes it easier to refer to each component and allows them to be taken into consideration accordingly.

BOM notes

They are any information besides the required data that may apply to the components.

Description

It refers to each material requirement and the final design product. It is comprehensive and informative.

It helps you distinguish between similar-looking parts and have an idea about each one’s functioning.

Part number

A number is created for each item or assembly to identify objects quickly and easily. It is a unique identifier and must be different from the code used.

Part name

It is an easily identifiable unique name for each part to refer to each item separately. It is the formal designation that distinguishes them from others.

Phase

It indicates the stage of each part in its production cycle. It helps you identify, track, and trace its production or demand.

Measurement Unit

It is a measuring unit of the items like inches, feet, ounces, drops, kgs, etc. It helps to track the correct quantities delivered to production.

Quantity

It is the number of items that are needed for a specific application. It may be the same modification as indicated in the description, but it does not have to be.

Type of procurement

It is a document that tells how each part is purchased. It helps to increase efficiency in the manufacturing and procurement process.

Source

It is a document that refers to where you obtain each part. Therefore, it helps determine if the correct number of components is supplied.

Material Group

It lists all materials with different characteristics, properties, and uses. It makes it easy for you to identify each material while making purchases.

The requirement

You must identify every part or assembly precisely to avoid any mistakes in the manufacturing process. It also helps you make sure no inventory is wasted. If materials are not required for production, they may be returned.

BOM management software

Most enterprise resource planning (ERP) solutions are available with BOM functionalities. In most modern cloud ERP solutions, it is a default functionality.

Maintaining an effortless BOM account is not as easy as it sounds. First, it makes choosing the right BOM software to create the seamless Bill of material you require.

Most companies use traditional software like Excel, but with the increased use of technology and complicated projects, specially designed BOMs are now available.

New technology develops advanced software with real-time monitoring capabilities and other deeper functionalities.

Full functionalities, highly sensitive inventory tracking, and smart status tags make modern-day Bill of Materials software unique.

Managing your labor and other manual resources becomes seamlessly smooth. Moreover, it draws a lot of pressure from the system and provides scope for other opportunities, thus increasing productivity and performance.

You can later switch over to detailed BOMs designed explicitly for your business. Many of the open-source ERP solutions have these functionalities in them.

The best software for managing it is,

Future of Bill of Materials

With the advent of technologies, future generations will soon take over modern technologies due to more effective communications, flexibility, and specificity.

The vision of OpenBOM is the beginning of real-time data collaboration and high-level data management.

The concept of OpenBom might give rise to a 24/7 global collaboration and synchronization, along with a hypersensitized network handling the significant workforce multiplied by many folds.

With OpenBOMs, a global initiative will be in sight, with instant data sharing, different teams, people, and groups accessing data from separate locations.

These new systems will give a prospective future in data AI or Artificial Intelligence. Therefore, upgrading oneself with the changing technology is essential to stay relevant and competitive.

Blockchain technology will make it open and transparent, which will help small manufacturers to gain market access quickly. It might be aimed at inventories for individual items and aggregated inventory.

Implementation of it depends on data-sharing tools like intelligent contracts sponsored by cryptocurrencies.

The Internet of Things (IoT) and blockchain-based IoT will allow information to flow quickly and easily between machines and installations using sensors. That will make it possible for manufacturers worldwide to get real-time data much faster than you might think.

FAQs

What is a Bill of Materials and why is it crucial in manufacturing?

It is a comprehensive list of all the components, materials, and sub-assemblies required to manufacture a product. It is vital in manufacturing as it serves as the foundation for production planning, inventory management, and quality control.

How does an accurate Bill of Materials contribute to efficient inventory management?

An accurate BoM helps in determining the exact quantities of materials required for production. This reduces excess inventory and minimizes carrying costs.

How does a well-structured BOM aid in quality control and product consistency?

It ensures that every product is assembled with the correct components and follows quality control standards, leading to consistent product quality.

What are some best practices for creating and maintaining an effective Bill of Materials?

Best practices include using standardized part numbering systems, clearly defining components and sub-assemblies, providing detailed descriptions, and ensuring regular updates.

Conclusion

BOM is a necessary part of your manufacturing procedure that cannot be left out whatsoever.

It is vital to consider all the information you can manage to figure out how to control the process and utilize the data.

Developing an efficient and seamless BOM is the stepping stone for a more detailed and valuable manufacturing process.

References