Are you on the lookout for a platform that can be the foundation of your organization and aid you in achieving cost-effectiveness and productivity? Well in that case computerized maintenance management systems empower you to seamlessly track work orders and assets, assuring a meticulous oversight of maintenance tasks.

A Computerized Maintenance Management System is a software application that helps organizations manage their maintenance operations. It enables users to track work orders and assets, schedule preventive maintenance tasks, and generate reports on facility performance.

It can help businesses save money by reducing downtime, improving equipment reliability, increasing efficiency, reducing costs, and optimizing production.

This blog post will explain what a computerized maintenance management system is and how it can help your business. You’ll learn about the different types of CMMS systems, their functionalities, best practices, and how they can benefit your company.

CMMS Software Definition

CMMS is a software application that helps organizations manage and schedule their facility’s maintenance activities. It electronically tracks work orders, parts, labor, and other related data.

Typically, this software integrates with other enterprise resource planning (ERP) software applications businesses use. This allows companies to have one system for managing all aspects of their business, from production to maintenance.

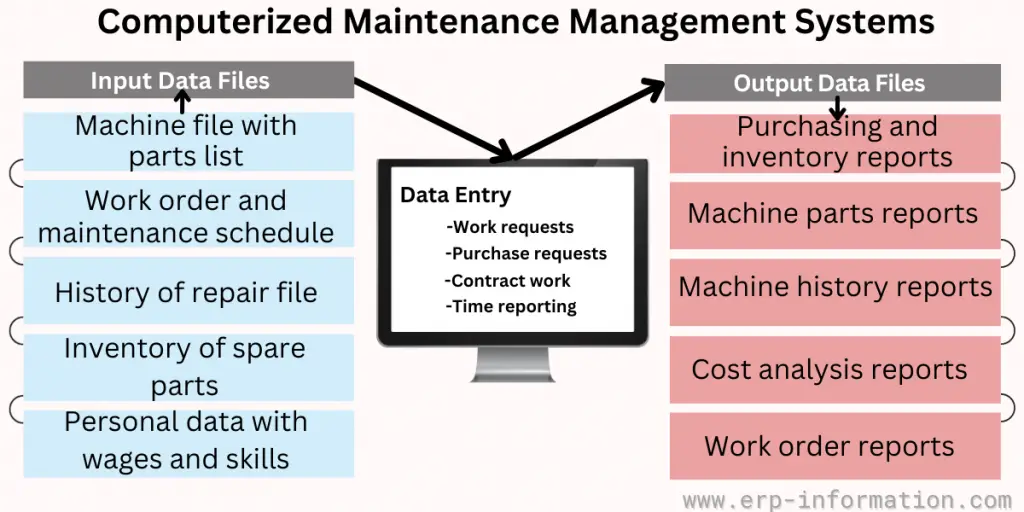

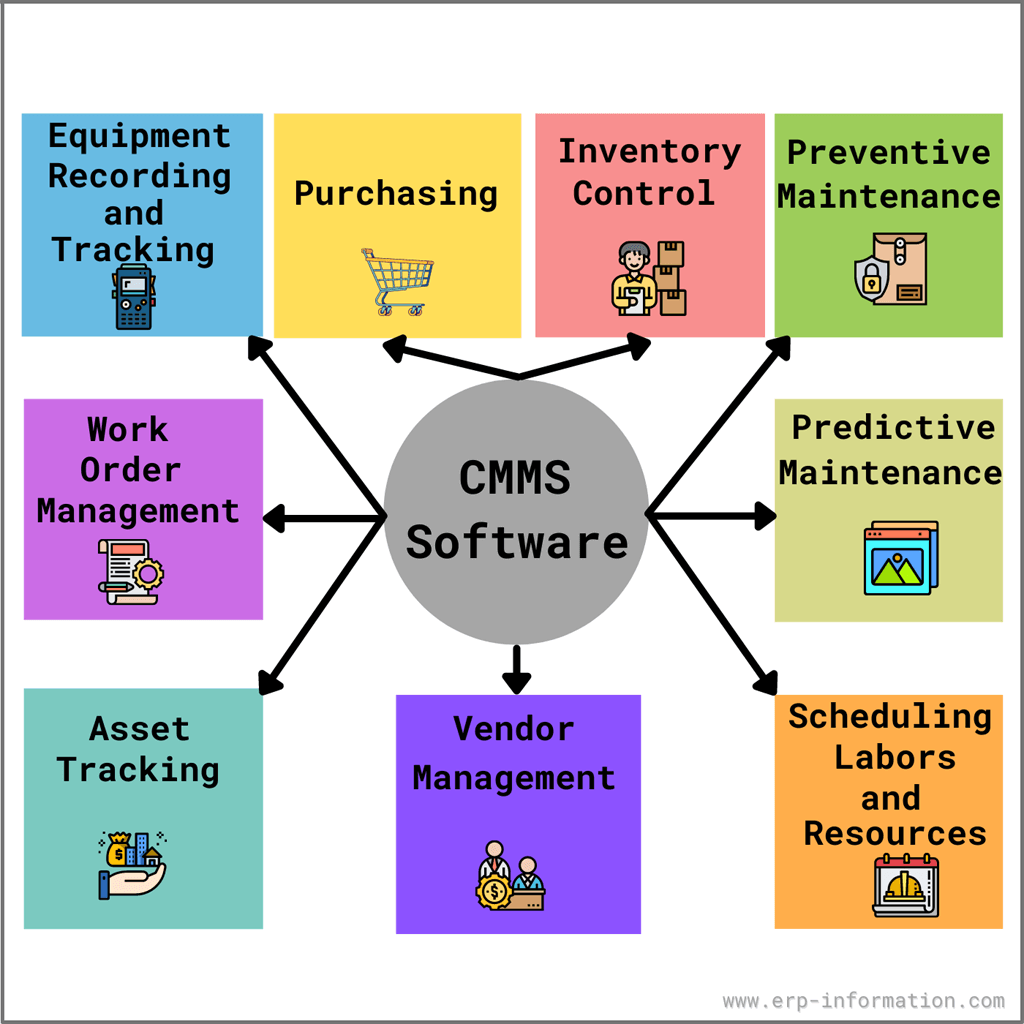

The data in CMMS do various functions and enable some capabilities. Some of them are

- Labor or resource management

- Work order management

- Asset registry

- Inventory management

- Preventive maintenance

- Reporting and analysis

Functionalities

Let us have a look at each of the functionalities.

Labor or resource management: Considers and tracks resource availability and assigns particular tasks. Organizes and monitors shifts.

Equipment recording and tracking: Tracks the availability of equipment and records the equipment certification.

Work order management: This functionality includes the following information:

- Work order number

- Description of work order

- Order type (repair, replace, scheduled)

- Priority

- Cause and remedy codes

- Personnel assigned and materials used

It helps to

- Automate work order generation

- Schedule and assign employees and shifts

- Reserve materials and equipment

- Keep track of planned and actual costs.

- Track downtime

Asset registry: CMMS software helps to store, access, and share the following asset data

- Model, manufacturer, and serial number of equipment

- Costs

- Warranties

- Location of equipment

- Performance and downtimes

- Manuals, safety procedures

- Sensors and IoT instruments

Inventory management: Equipment maintenance and repair operation in the storage location. Tracking inventory, inventory costs, managing suppliers, and automatic resupply.

Preventive maintenance: Organizes assets across multiple orders, schedules preventive work orders, and reduces equipment downtime.

Mobile maintenance: With the help of mobile devices like smartphones, the technician or maintenance team members can access system data.

Reporting and analysis: Automatic generation of reports on asset availability, materials usage, resource utilization, material costs, and more. It analyzes the real-time data to know performance trends, asset availability, and inventory optimization.

It is helpful to the industries like hospitals, oil & gas production, manufacturing, power generation, construction industries, transportation, government, etc.

How Does It Work?

Let us know the detailed working of CMMS.

When a work order is generated, it is assigned to a webmaster, maintenance team, and equipment.

The webmaster or technician updates the work order with new data like meter readings, time spent, etc., and the work order is completed.

Now, computerized maintenance management systems process these data and update the records of the asset. In addition, it can be programmed to find out the difference in asset conditions.

If the equipment crosses the predefined threshold line, an email is sent automatically to the technician or maintenance team members.

Computerized maintenance management systems allow the organization to set the system as per its requirements. For example, an administrator can create a mandatory field that the technician should fill in before closing the work orders.

It helps to complete the entry with valuable data and generates accurate reports. Then the management of the organization takes the reports and analyzes them.

Types of CMMS

Generally, a computer maintenance management system is divided into two types.

On-premise: Maintenance data is managed by an in-house software system in this system. In this system, installing new features and managing infrastructure is your responsibility.

Cloud: In this system, infrastructure management is hosted by a CMMS provider. New features update automatically.

With the help of a cloud computerized maintenance management system, you can enter the data from anywhere. For example, a technician can view and update work orders using the mobile application.

History

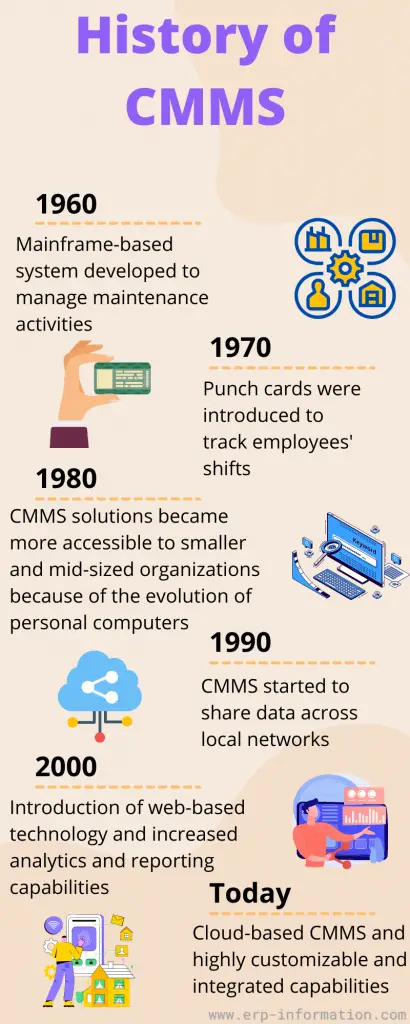

Before the 1960s, all information was in paper files and scattered. Hence, it wasn’t easy to get centralized visibility and automated management.

The history of computerized maintenance management systems can be dated back to the early 1960s when the first mainframe-based systems were developed to manage maintenance activities in large manufacturing plants.

These early systems were primarily used for maintenance tasks and tracking work orders.

In the 1970s, punch cards were introduced, and technicians started using that to track their shifts.

In the 1980s, with the evolution of personal computers and client-server technology, CMMS solutions became more accessible to smaller and mid-sized organizations.

In the 1990s, CMMS started to share data across local networks. That led to increased adoption across various industries, including healthcare, hospitality, and public utilities.

Throughout the 1990s and 2000s, CMMS solutions continued to evolve and become more sophisticated. The introduction of web-based technology and increased use of the internet allowed for increased mobility and real-time data access.

At the same time, advances in analytics and reporting capabilities enabled organizations to gain deeper insights into their maintenance operations.

Today, cloud-based CMMS solutions are highly customizable and mobile and can integrate with other enterprise systems, such as asset management software or supply chain management tools.

In addition, they offer a range of features beyond basic work order management, including inventory management, vendor management, predictive maintenance capabilities, and more.

Modern computerized maintenance management software provides easy implementation, maintenance, and proper security.

Advantages of Computerized Maintenance Management System

The system offers several benefits to organizations that rely on equipment or assets. Here are some of the key advantages:

Improved equipment reliability

The system helps organizations to avoid breakdowns and extend the life of their equipment by tracking and scheduling preventive maintenance tasks.

Improved asset management

The system provides centralized information, so maintenance managers can easily track purchasing of assets, asset performance, breakdowns, efficiency ratings, etc.

Workflow visibility

Dashboards assess the work’s status and progress in real time, which improves workflow visibility by finding where an asset is, and who has to handle it when it should work on it.

Enhanced safety

By ensuring that equipment is properly maintained, the solutions can help reduce the risk of workplace accidents or injuries and maintain a healthy operating environment.

Automation

The system helps to automate routine maintenance tasks like work order creation and parts ordering, inventory scheduling shifts, and MRO inventory. It helps to reduce errors, save time, and improve productivity. In addition, it frees up staff time for more strategic activities.

Better inventory control

Many CMMS solutions include inventory management capabilities, allowing organizations to optimize their parts inventories and reduce waste.

Real-time data access

With web-based CMMS solutions, staff can access real-time data about equipment performance from anywhere with an internet connection, allowing for faster decision-making and issue resolution.

Field workforce management

The CMMS system helps to unify and deploy internal and external resources. The late solutions provide good connectivity, augmented reality, and blockchain technology to handle field operations.

Preventive maintenance

The CMMS system provides real-time data on equipment with the help of sensors, meters, and IoT instruments. So provides preventive measures and alerts you about failure or underperformance of the equipment.

Knowledge transfer

It stores the respected assets’ repair manuals, documentation, and maintenance procedures. Then, it transfers those preserved details to the new technician.

Regulatory compliance

For organizations operating in regulated industries such as healthcare or manufacturing, CMMS solutions can help ensure compliance with industry-specific asset maintenance and record-keeping regulations.

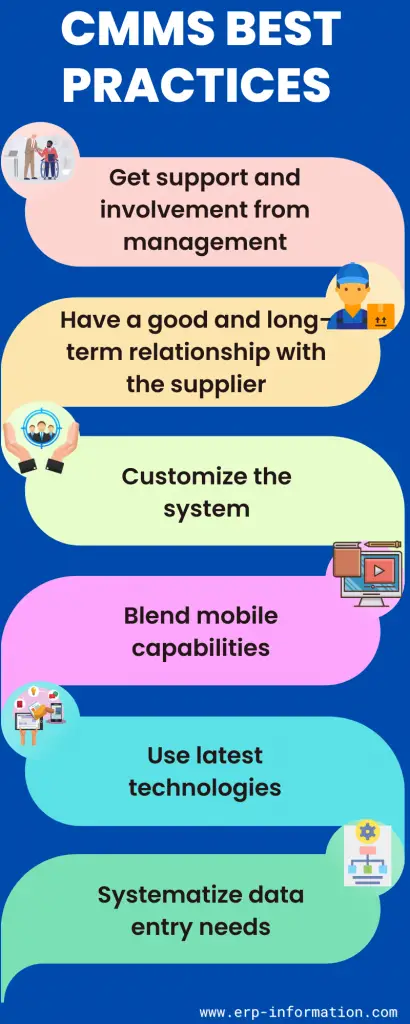

Best Practices

Below is the list of best practices for computerized maintenance management systems. After adopting it, you face problems like inaccurate data, less completion value, etc. To avoid these problems, know the best practices.

Get support and involvement from management

To take full advantage of computerized maintenance management systems, the involvement, and support of management are very important.

Let the management explain and demonstrate the impact of CMMS on the overall development and success of the organization.

Have a good and long-term relationship with the supplier

Keep on communicating with the vendors even after purchasing CMMS to update yourself about the upcoming software updation, new features of the system, etc.

Customize the system

Make adjustments to the system as per your requirements. For example, some features in the system may not be helpful, which leads to confusion while operating. Hence to avoid this problem, customize the system and make it easy to use.

Blend mobile capabilities

Allow the technicians to use CMMS on their smartphones to work even though they are traveling or moving from one department to another. Let them have access to the system everywhere they go. Again, it helps to save time.

Use latest technologies

To make data-driven decisions, use the latest technologies like data analytics, AI, the Internet of Things devices, and machine learning.

These technologies allow you to analyze previous data and decisions. Internet of Things device will enable you to monitor and control machinery remotely and run real-time data into the CMMS.

Systematize data entry needs

CMMS helps to deposit valuable information about repair history and assets operating. However, getting accurate and meaningful data without coordination between data entry team members isn’t easy.

Hence discuss with your vendor and standardize the data entry needs so that all users enter the standard data.

Computerized Maintenance Management Systems Software

Following is the list of software

- Smartsheet

- EZOfficeinventory

- TeroTAM

- GP Mate

- ManWinWin

- Asset Panda

- UpKeep

- FMX

- eSpace

10 Best CMMS Inventory Management Software Solutions

Difference Between CMMS and EAM

Both computerized maintenance management systems and enterprise asset management (EAM) are asset management systems. Some similarities are there between them, and some differences are also there. We focus on differences.

| CMMS | EAM |

| It is less comprehensive | It is more comprehensive |

| Not all CMMS have EAM functionalities | EAM solutions have some CMMS functionalities |

| It is for a company with less maintenance staff | It is for a company with more mechanical maintenance staff and IT maintenance staff. |

Conclusion

CMMS systems serve as computer programs designed to schedule, monitor, and oversee preventive maintenance tasks and work orders within industrial or commercial facilities.

These versatile systems find application across diverse industries, such as manufacturing, healthcare, hospitality, education, and government.

Comprising three fundamental components—the database, software application(s), and user interface—the database is the repository for all asset-related information, including equipment details like make, model number, and serial number.

Leveraging this stored data, the software applications efficiently generate work orders and reports. Moreover, the user interface enables users to input data (e.g., PM tasks) into the system and access reports for viewing or printing. We trust this blog post has enhanced your understanding of CMMS systems.