Are you tired of relying on primitive spreadsheets and outdated planning techniques that cannot keep up with the fast-changing, unpredictable supply chain?

A digital twin can be a game-changer! It gives businesses powerful insight into how their strategy will perform in different scenarios.

This means companies can ensure they have an agile design ready for anything – from blocked transport routes to unexpected shutdowns at distribution centers. Investing in a digital twin is essential for building long-term resilience within your logistics network.

In this blog post, we’ll take an in-depth look at the power of digital twin in supply chain landscape by exploring its benefits as well as the potential challenges it faces.

What is digital twin in supply chain?

The digital twin is a sophisticated analytical tool for monitoring equipment performance and optimizing operations processes.

By leveraging real-time insights, augmented reality (AR)/virtual reality (VR), dynamic simulations, predictive analytics, and artificial intelligence (AI) capabilities within a shared platform—the “digital twin”—companies can speed up decision-making significantly while improving predictions on how products will function in real life scenarios.

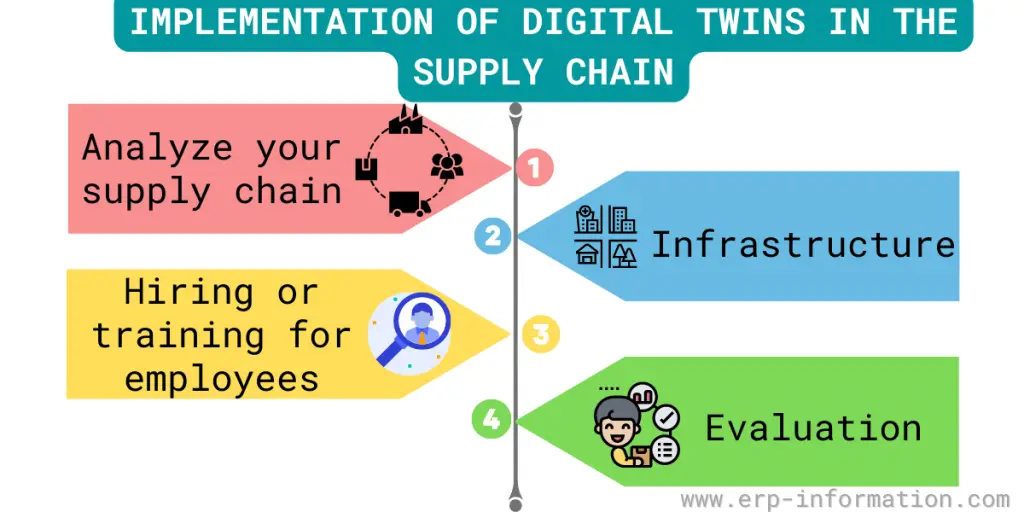

Implementation of the digital twin in the supply chain

Digital twins have become increasingly popular in the supply chain due to their ability to simulate complex systems and processes. As a result, companies are investing more time and resources into implementing digital twins to stay competitive.

Analyze your supply chain

Before beginning implementation, it is important for companies to thoroughly analyze the current supply chain operations to identify areas for improvement or opportunities for automation.

Supportive Infrastructure

Companies should also ensure an infrastructure supporting digital twin technology. Once these analyses are complete, businesses can develop a strategy for implementing digital twins into their supply chain process.

This may involve integrating existing data sources with machine learning capabilities or investing in new technologies such as IoT sensors or AI platforms.

Hiring or training for employees

Obtaining a comprehensive digital twin for your organization requires finding the ideal personnel and keeping an eye on and managing operations.

Investing in specialists to generate, trial run, and carry out solutions will go a long way toward recognizing any issues before they become more serious problems.

Evaluation

The team should conduct regular tests and evaluations to ensure that the digital twin aligns with the company’s goals and objectives for its supply chain operations.

Benefits of implementing a digital twin in the supply chain

The benefits of implementing a digital twin in the supply chain include

Enhanced visibility

It Increases efficiency and visibility across the entire supply chain. Digital twin technology is transforming the way companies manage their supply chains.

- It is more accurate demand forecasting.

- By creating digital twins of physical assets in the supply chain, digital twin technology enables businesses to increase visibility and efficiency across every stage of production and delivery.

- Digital twins provide accurate digital depictions of the physical products that make up a company’s goods and services, making them invaluable for operational tasks such as monitoring inventory levels, tracking supplier-to-customer shipments, expediting problem resolution, reducing downtime, and improving overall efficiencies in production processes.

- Digital twin technology is essential for companies looking to improve their supply chain management and performance.

Improved risk management

The ability to detect and respond to disruptions in near-real time. By utilizing digital twin technology, businesses can manage risk and discover the best possible action in an emergency while testing different scenarios to improve organizational stability dramatically.

- The digital twin allows entities in the supply chain to create a digital representation that simulates the physical asset or system,

- It allows them to have real-time insights and more accurate predictions and forecasts.

- It prepares different scenarios and contingency plans for upcoming emergencies.

- It bridges existing data flows between people, processes, and systems to enable decision-making in a digital space, making digital twins an invaluable resource for supply chain companies.

Increased efficiency

Every supply chain comes with risks and areas of vulnerabilities. Traditionally, the only way to identify these weaknesses was by trial and error and analyzing the results post-implementation. Thankfully, digital twins have changed this process drastically –

- It Improves quality control and reduces product defects.

- Digital twin simulations allow companies to run complete digital replicas of their supply chains with specific changes to test how they will impact current operations before they’re implemented.

- This analysis also allows companies to predict how productivity may be affected.

- Through digital twin simulations, supply chain managers now have a predictive tool to increase efficiency and reduce unforeseen fallout from unprepared transitions.

Transportation

Digital twin in the supply chain offers many advantages for managing a business’s transportation resources.

- Digital twins enable supply chain management to rapidly assess and adjust their operations in real time based on changes in customer demand and product availability.

- By leveraging digital twin technologies, they can quickly determine the physical locations and system components that must be adjusted to meet shifting market needs while satiating the end customer.

- Utilizing predictive analytics, digital twin technology can provide invaluable insights to help streamline transportation networks with extraordinary precision.

Optimize inventory

It reduces inventory levels and improves cash flow. Digital technology also allows businesses to optimize inventory levels and reduce overhead costs, enabling them to remain competitive in global markets.

- The ability to forecast accurately with data analytics reduces the costs associated with overstocking or under-stocking items and decreases waste generated by expired inventory.

- By leveraging digital models of physical world events and activities, digital twins can crunch data from demand forecasting processes to make predictions that help avoid stock-outs and minimize overall costs of production and warehousing.

Lower costs

Digital twin technology across the supply chain, offering better end-to-end visibility while maintaining cost efficiency.

- Digital twins also allow leaders to monitor performance consistently, providing insights into how operational changes might impact future outcomes or identify new opportunities for optimization.

- As digital twins continue to increase and become more sophisticated, technology is positioned to become an integral part of supply chain digitalization.

- Greater flexibility to respond quickly to changes in demand or supply.

Drawbacks

- Need a consistent internet connection

- Specialists to be hired or trained the existing employees for implementation

- Continuous evaluation is required

- This will need to be across the supply chain

FAQs

How can the use of digital twins help to improve performance in the supply chain?

Companies can now improve their supply chain efficiency with the help of digital twins featuring embedded AI. These innovative simulations allow companies to analyze and manage a broad range of costs, service levels, and emissions – unlocking new possibilities for profitable growth.

What industries use digital twin technology?

The digital twin is efficiently used by

Manufacturing

Supply chain

Construction

Health care

Automotive

Architecture

Retail industries.

Conclusion

Digital twins can profoundly impact the efficiency, accuracy, and overall performance of a company’s supply chain operations.

By leveraging these technologies, companies can gain enhanced visibility into their supply chain processes, improve risk management and achieve increased efficiency through automation.

With careful planning, strategic implementation, and ongoing evaluation, businesses can reap the full benefits of digital twin technology in their supply chains. We hope this blog post has answered your doubts and questions.