A dispatch list is a resource used in manufacturing to ensure the accurate and timely delivery of required components and materials to the assembly line. This ensures that production is operating seamlessly and adhering to the designated schedule.

It also helps keep track of inventory levels and makes it easy to identify which parts need to be ordered. In a nutshell, the dispatch list is an essential part of any manufacturing operation.

In this blog post, we’ll look closer at the definition of a dispatch list, its format, and its advantages.

Definition

A dispatch list is a detailed, sequential log of manufacturing work orders or rate schedules, encompassing critical information such as location, quantity, capacity requirements, and listing of all the goods that need to be produced based on priority.

Generating these dispatch lists daily for each work center or production line is essential to ensure smooth and efficient operations.

It is generally shared with the production team via the internal system or a hard copy. It holds all the essential information that the production team must know before starting their jobs.

Creating a dispatch list is crucial as it translates production planning into action. Hence, it is also essential to check the inventory and demand before communicating to the respective production team.

In manufacturing, companies frequently need to complete the production of one item entirely before transitioning to the next product. Consequently, once a production run begins, it cannot be reclassified into inventory or as an active order until all production orders are fully completed.

These production runs typically precede inventory orders, unless they are actively being processed in response to customer service requests for repairs or returns.

This approach ensures that no tasks are left incomplete during periods of high demand. Additionally, it allows for more downtime between production runs for essential activities such as cleaning, reducing the likelihood of delays in order fulfillment.

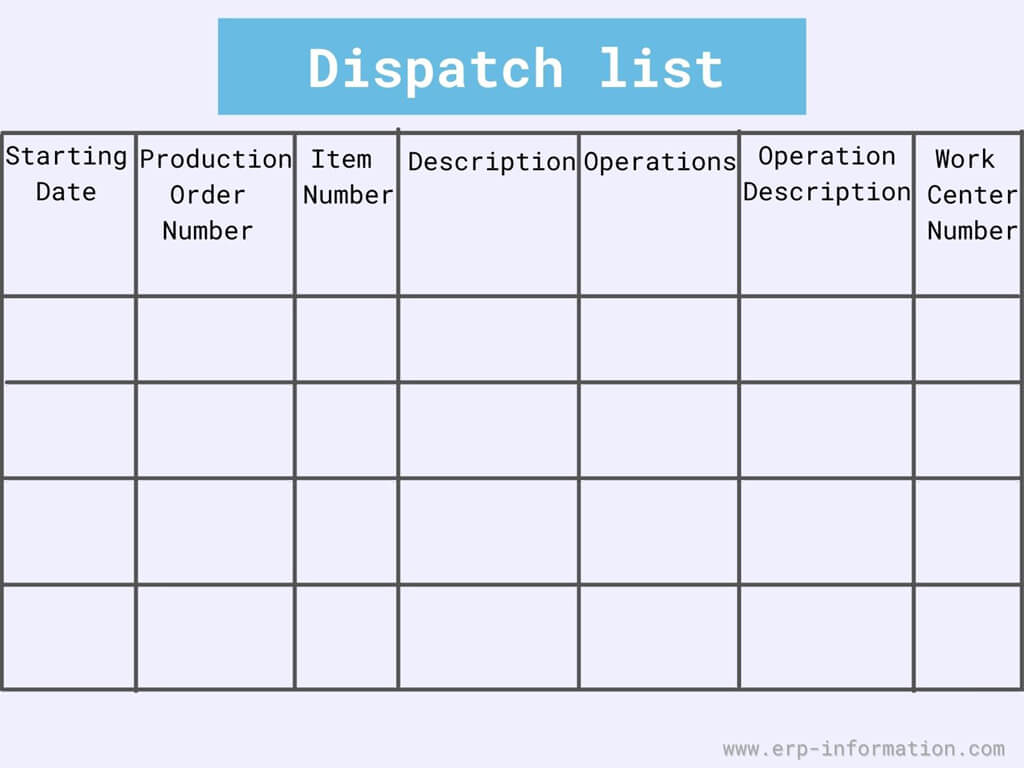

Dispatch List Format

The dispatch list consists of various critical details, such as the cost breakdown for each product, the labor requirements for assembly, and the necessary materials that must be procured prior to initiating the manufacturing process.

These lists are usually dated or numbered with their time slots to know which order they should work in according to when they come in each morning.

Dispatch lists are an essential part of packing up products at the end of the day because they help workers decide which packages must be sent out first.

Advantages

- It aids in determining the optimal production order and assigning suitable tasks to workers based on their abilities and expertise.

- It facilitates the meticulous planning of a step-by-step production schedule, guaranteeing seamless operations and meeting the anticipated demand within a specified timeframe.

- It enables the implementation of a production plan, initiating prompt action to bring it to fruition.

- Each workstation is assigned a specific task, providing managers with clear expectations for the day and serving as a motivational tool to drive the workforce toward achieving their objectives.

The dispatch list helps organize and manage the manufacturing process. It ensures that each step is completed correctly and that the correct parts are available when needed. This reduces waste and improves efficiency.

Additionally, dispatch lists can help identify potential problems before they cause severe disruptions in production. Finally, dispatch lists can help to ensure that safety regulations are followed throughout the manufacturing process.

FAQs

How to create a dispatch list?

To create a dispatch list, you will need to identify the following information for each task:

Task name

Due date

Priority

Assignee

Status

You can then use a variety of tools to create and manage your dispatch list, such as a spreadsheet, project management software, or a customer relationship management (CRM) system.

Conclusion

As discussed in this blog post, there are many ways that dispatch lists can be used to increase efficiency and reduce the amount of time spent on tasks.

Dispatching is a vital manufacturing area for any company that wants its products to come out quickly with high quality.

The key is knowledge; you must know when it’s appropriate to use each type of dispatch list, so your team spends less time figuring things out during production.

Get more definitions about similar topics and other ERP-related terms here.