Global supply chains are interconnected and interdependent physical and digital entities, managing the flow of goods and services from origin to the end of consumption.

The global supply chain is becoming increasingly important in today’s business world due to its ability to help companies operate more efficiently and effectively globally.

This blog post will help you to understand the Global supply chain(GSC), global supply chain management, areas of supply chain management, strategies, factors that influence the global supply chain, benefits, and drawbacks.

What is a global supply chain?

A global supply chain is like a big network. It connects an organization with the people and places that help it get its needs and then turns them into products to sell. All kinds of things are part of this network, like activities, people, technology, information, and resources.

Benefits of global supply chain

- It helps streamline processes, reduce costs, and increase profits by taking advantage of favorable labor costs in different parts of the world and optimizing transportation routes.

- It enables companies to tap into new markets and access resources that may otherwise have been unavailable.

- Using technology like Artificial intelligence(AI) and data analysis, companies can get information from around the world to help them make choices faster. This gives them an advantage in a quickly changing world.

What is global supply chain management?

Global supply-chain management means moving goods and services worldwide to get the most money and use as little as possible. It is similar to regular supply-chain management, except it works for companies operating in different countries.

Global supply chain management is about planning how to get products to customers quickly and cheaply. It includes managing suppliers, manufacturers, warehouses, and stores. This ensures that the right goods are bought, made, and sent out.

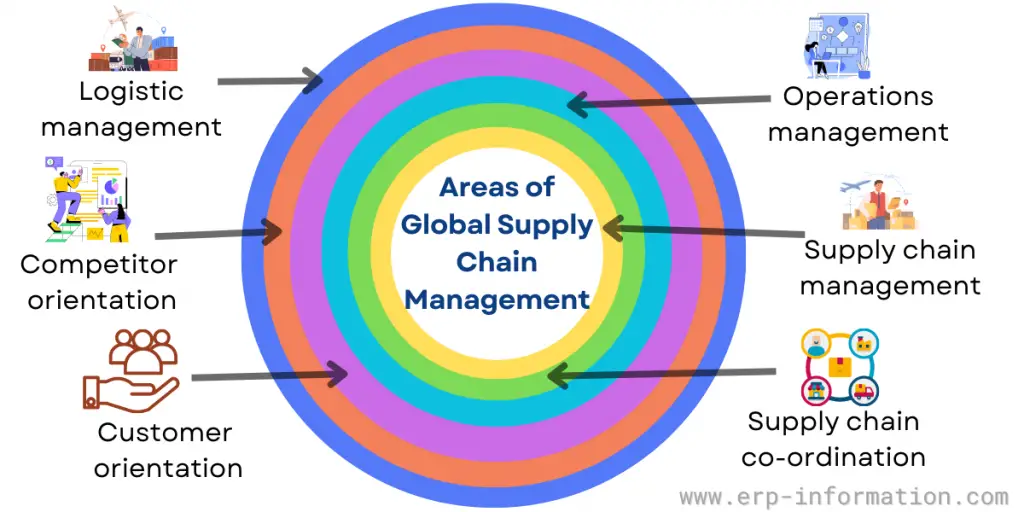

Areas of global supply chain management

The global supply chain includes six main areas.

Logistic management

Logistics is about ensuring the right things are in the right place and right time. It is part of supply chain management, which keeps everything organized. Logistics involves moving goods, services, and information from one place to another. This includes tangible items like materials, supplies, and food.

Competitor orientation

Competitor orientation is focused on beating other companies instead of making the most money. Even though it is not the best way to make money, it works in business.

Competitive businesses need to think about how they compare to their competitors. They should look at how quickly they can make products, their prices, how happy customers are with them, and more.

Customer orientation

Businesses that sell things to the public need to have a good reputation. They need to make sure customers are happy. As a result, retail companies compete by offering low prices, high quality, and good services. This is different from businesses that buy or produce materials.

Supply chain co-ordination

A supply chain is a system with different places that turn raw materials into finished products and get them to where they need to go. Supply chain management ensures the products move through this system most effectively.

Supply chain management

Supply management, called procurement, is how businesses buy things they need. It could be to get supplies for their use or to make something new. It could also be to buy things they will sell later.

Supply management helps a business in many ways. First, it looks at the materials and services that come into the business and ensures they are used correctly.

It also works with suppliers to get more materials and assistance when needed. It is like a plan for what comes into the business, how it is used, and how to get more if it runs out.

Operations management

Operations management is a part of the business. It means ensuring that companies use as few resources as possible to make goods or services and meet the customer’s needs. This helps the business use fewer materials, time, and money.

Operations is a way to manage the process of getting things done. This includes taking materials and energy, adding labor, and providing goods or services to consumers. Operations help produce products, ensure they are good quality, and help create customer service.

Factors that influence successful supply chain management

Supply chain management is important for any organization. Everyone in the company needs to work together and with people outside of the company to make it successful. It involves people, processes, and technology.

People: People are important in supply chain management. They need to know how to get, make, store, and ship the products. They must also understand what the company is trying to do and how their job fits that plan.

Process: Supply chain management is all the steps needed to make customers happy. These processes include finding and buying items, getting them to the customer, storing them, selling them, and giving customer service. It also has anything done by outside companies that help with supply chain management.

Technology: Technology helps people work together and do things faster. But people will not use it if it is too hard to learn. So companies must choose the right technology and use it correctly for their supply chain to succeed.

Strategies

Investing in the right technology

Companies should buy the right technology to make their supply chains work well and stay safe. This includes purchasing things like automation, data analysis tools, and tracking systems that tell them what is happening in real-time.

Strong partnership

Companies should work with other companies and people who can help them. This will make sure that everyone is working together to make the supply chain better for everyone.

Tracking

Companies should watch and keep track of goods and services being sent to different places. This helps make sure the global supply chain is working correctly.

Communication

Companies should ensure everyone involved can talk to each other. This will help avoid confusion and mistakes.

Future planning

Companies should think ahead and plan for things that could go wrong, like if they break the law or someone tries to attack them.

Benefits of supply chain management

Save money

Global supply chains help businesses save money. Companies can get materials from other countries with cheaper labor and production costs. This allows them to make their operations more cost-efficient.

Flexibility

Global supply chains help companies make changes fast. They can change their operations to match what customers want. This helps when there is a new product or a change in what people want to buy.

Quality improvement

Global supply chains can use the newest technology and data to check the quality of their products. This will help customers be more satisfied and loyal.

Increase productivity

Global supply chains are made to work well. Companies use processes and technology to make sure they do not waste anything or take too much time. This helps them be more productive.

Business expansion

Global supply chains help companies grow. They can reach new customers and make more money.

Drawbacks of supply chain management

Supply-side risk

Supply-side risk ensures companies can give customers what they need. It includes issues that happen when supplies come from far away like it taking a long time to get the items and suppliers not having the same quality standards as the company.

Demand-side risk

Demand-side risk is when companies don’t have enough products to meet customers’ needs. This can happen if more customers want the product than the company can supply.

Regulatory risk

Global supply chains must follow laws and rules in many countries. This can be difficult, and you may get a fine or punishment if you don’t.

Lack of visibility

The global supply chain involves lots of different people. It is a bit difficult to keep track of all the goods and services that are being moved around. This can cause things to take longer than expected and not work as well as they should.

Complexity

Global supply chains involve many people and can be very complicated. This means it will cost more money and take longer for things to get where they need to go.

Multi-language and culture

Global supply chains involve people from different countries. This can lead to issues because they may not speak the same language or understand each other’s cultures. This can confuse and make it harder for things to work properly.

Security risk

This can be at risk from cyberattacks, data losses, and theft. Companies must spend money on the right tools and processes to keep their global supply chains safe.

Expensive shipping

It can be expensive to ship items from far away. This is because bringing them across the world takes a long time.

FAQs

What are the major issues of global supply chain management?

Energy, Weather, and geographical uncertainty are major issues. Energy is becoming harder to get, and it costs more money. Countries are not getting along with each other. The Weather has been extreme lately, causing more problems.

What kind of jobs are available for supply chain management graduates?

If you major in Supply Chain Management (SCM), you will be ready to start a job in buying or logistics. Possible careers include buyer, purchasing analyst, inventory control, and traffic analyst.

You could also become procurement, operations, or logistics, vice president. Companies from many different places and industries hire SCM graduates. Examples are public and private firms that make things give services, and work in health care and retail.

What are the skills to build a supply chain career?

The study showed that when employers hire people for supply chain jobs, they look for people with good analytical skills, quick learning, organization skills, and the ability to prioritize and plan. They also look for people who can communicate well with others and work well in a team.

Conclusion

The global supply chain is becoming increasingly important in today’s business world due to its ability to help companies operate more efficiently and effectively globally.

It helps streamline processes, reduce costs, and increase profits by taking advantage of favorable labor costs worldwide and optimizing transportation routes.

Companies can use global supply chains to reach new markets and get resources they might not have before. In addition, they can use AI and data analysis to make better decisions faster. This helps companies stay ahead of the competition in a world that is always changing.

We hope this blog post is successfully provided the complete details of the global supply chain.