Companies have always been driven by the desire to grow, reduce costs, improve efficiency, and distinguish themselves from competitors.

In pursuit of these goals, businesses employ various strategies, with Horizontal Integration and Vertical Integration emerging as popular methods.

By strategically employing these integration methods, companies can achieve their objectives of growth, cost reduction, efficiency improvement, and differentiation.

They can adapt swiftly to market changes, capitalize on market opportunities, and differentiate themselves from competitors.

These strategies eventually position companies for long-term success in an ever-evolving business landscape.

You may have heard of the terms Horizontal Integration and Vertical Integration but may not know what they mean.

Even if you understand the concepts, seeing how they apply to your business can be hard.

We’re here to help! This post will explain horizontal and vertical system integration, give some examples, and show you how Industry 4.0 is changing the game.

What is Horizontal and Vertical System Integration?

Understanding the integration

Imagine a company as a tree, its branches reaching horizontally and its roots growing deeper vertically.

Horizontal integration expands the company’s reach, increasing its market share and diversifying its products.

This strategy reduces competition while allowing for economies of scale and enhanced growth potential.

On the other hand, vertical integration strengthens the company’s foundation by deepening its roots.

By gaining control over various stages of the supply chain, the company can reduce costs, improve efficiency, and ensure quality.

This strategy also enables the company to differentiate itself from competitors, as it has greater control over critical aspects of its operations.

What is Horizontal Integration?

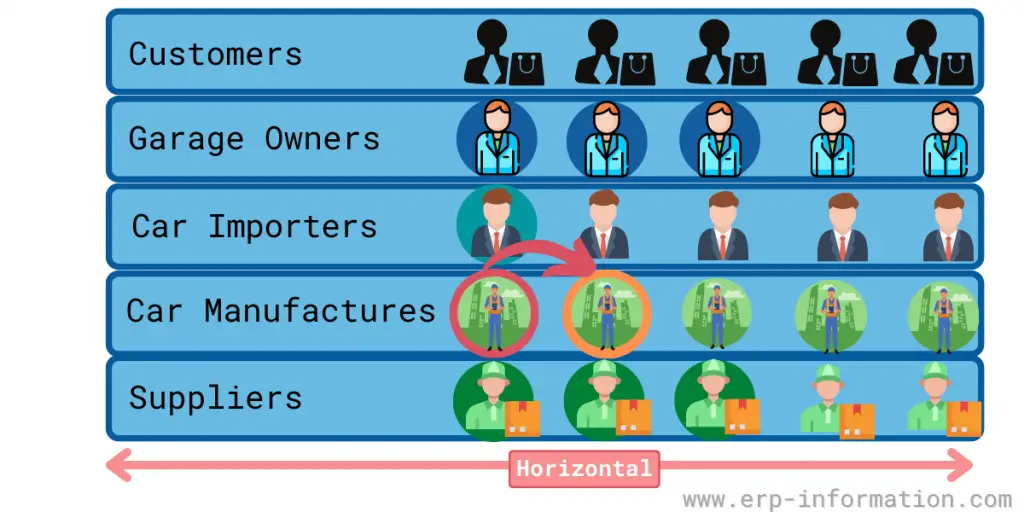

A horizontal integration system is a business strategy companies use to increase their market share.

It involves the acquisition of other companies that produce similar products or services. This allows the company to combine resources and create a larger, more competitive entity.

Some examples

- The merger of two competing banks

- The acquisition of a company by a more significant retailer

- A joint venture between two companies to develop a new product

- A company that manufactures tires may acquire or merge with its competitive company.

Goals

- To achieve efficiencies through economies of scale

- To create a more competitive market

- To produce and distribute products and services at a lower cost

- To increase market share and profitability

- To innovate and improve customer service

What is Vertical Integration?

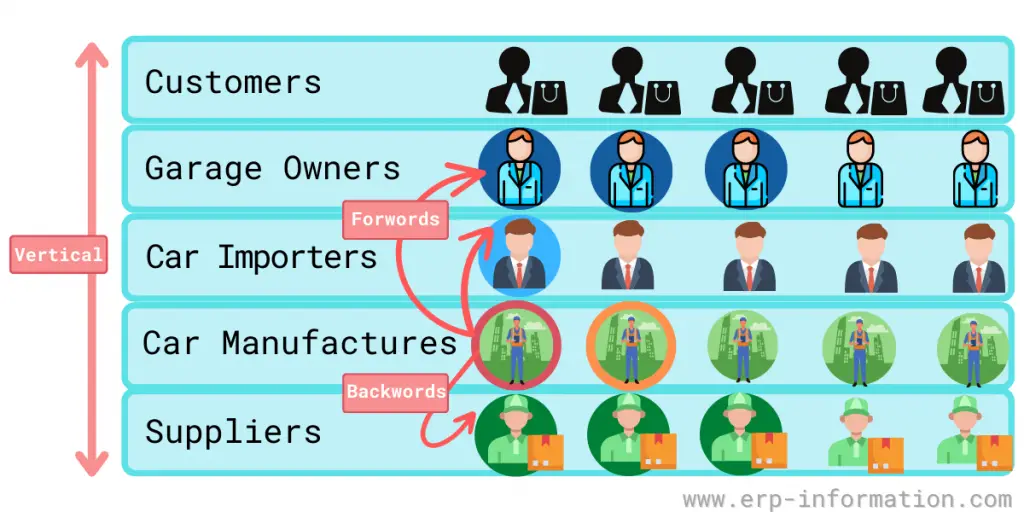

Vertical integration is a business strategy that companies use to gain control over the entire production process. It refers to the integration of different levels of a company or organization.

This can be done by integrating other parts of the supply chain or connecting different levels of the organization (such as R&D, manufacturing, and sales).

This integration allows companies to achieve economies of scale and improve their bargaining power with suppliers and customers.

Some examples

- The merger of a distributor and a retailer

- A joint venture between a car manufacturer and an auto parts supplier to develop a new car model

We can classify vertical integration into three types: forward integration, backward integration and one more is balanced integration.

Forward Integration

- Forward vertical integration is when a company controls its distributors or retailers.

- It can be done through ownership, long-term contracts, or other arrangements.

- Forward vertical integration can help a company to expand into new markets and increase market share. For example, a bike or car manufacturer may acquire an automotive dealership and improve market share.

Backward Integration

- Backward vertical integration is when a company controls its suppliers.

- It can be done through ownership, long-term contracts, or other arrangements.

- Backward vertical integration can give a company more control over its supply chain and help to reduce costs. For example, a bike or car manufacturer acquires a company that produces vehicle tires or an automobile spare part manufacturing company.

Balanced vertical integration means, adopting both forward and backward vertical integration.

Horizontal and Vertical Integration in Industry 4.0

In a traditional manufacturing setting, businesses would generally operate independently from one another, with little to no communication or collaboration.

That often resulted in inefficiencies and duplications of effort, as each company would reinvent the wheel.

Industry 4.0 changes this by creating a more interconnected system where businesses can share information and resources more efficiently.

That allows for a more coordinated approach to manufacturing, leading to greater efficiency and flexibility.

In Industry 4.0, horizontal and vertical integration work together to create a more efficient and interconnected system. Horizontal integration refers to integrating multiple businesses or organizations within the same industry.

In contrast, vertical integration refers to integrating different production stages within the same company. By combining these two processes, Industry 4.0 creates a more streamlined and efficient system that can better adapt to the market’s changing needs.

Pros and Cons of Horizontal Integration

Pros

Reduced competition

When companies engage in horizontal integration, they acquire or merge with their competitors, resulting in reduced market competition. This can be advantageous for the business.

Increased market share

On acquiring a competitor, it is probable that the company’s market share will grow. The company gains an increased authority and leverage over pricing, while also facilitating the attainment of economies of scale.

Economies of scale

Horizontal integration in a company often leads to the attainment of economies of scale, enabling the production of goods and services in a more efficient and cost-effective manner compared to competitors.

Increased revenue

A company with a larger market share often charges higher prices for its products and services. That can lead to increased revenue and profits.

Decreased production cost

In horizontal integration, two or more companies may join forces to share resources and decrease production costs. It can be advantageous for both companies involved.

Cons

Complications with coordination

When two companies merge, coordinating their activities cannot be easy. That can lead to inefficiencies and higher costs.

Cultural differences

Integrating their employees and operations cannot be accessible when companies from different cultures merge. That can lead to tension and conflict within the company.

Loss of customer choice

When fewer companies are in a market, customers may have fewer choices. That can lead to higher prices and decreased customer satisfaction.

Pros and Cons of Vertical Integration

Pros

Greater control over the supply chain

By owning more of the companies in its supply chain, a company can exert greater control over the quality and cost of inputs, ultimately resulting in a higher quality product for the consumer.

Decreased production costs

When a company vertically integrates, it can often control the entire production process from start to finish. That can lead to decreased production costs and increased efficiency.

Enhanced sales

A company on vertical integration may be able to sell its product for a higher price. This is because the company has more control over the quality of the product and can charge a premium for a high-quality product.

Cons

Risk of over-investment

When a company vertically integrates, it often requires a significant up-front investment. This can lead to financial problems if the integration is not successful.

Loss of focus

A vertically integrated company may lose sight of its core competencies and become distracted from its main business goals.

Increased organizational and coordination costs

Managing a larger and more complex organization is a challenge that a vertically integrated company may face. This can result in higher coordination costs and inefficiencies within the company.

Real-life Examples of Horizontal and Verticle System Integration

As we discussed earlier, Horizontal system integration involves combining or merging different companies operating at the same supply chain level or producing similar products or services. Here are some real-life examples of horizontal system integration:

- Disney streaming services acquired BAMTech in 2016, which allowed Disney to expand its already extensive media and entertainment empire into the superhero genre and related merchandise.

- The acquisition of 21st Century Fox by Disney in 2019 allowed Disney to acquire Fox’s movie production and distribution businesses, as well as their television and cable networks, giving Disney greater control over the production process of their content.

- The merger between the pharmaceutical giants Pfizer and Wyeth in October 2009 combined their respective drug research and development programs and expanded their product lines.

- The merger of luxury car manufacturers Fiat and Chrysler Group LLC in 2014 allowed both companies to share technology, production facilities, and R&D resources while strengthening their position in the highly competitive global automotive market.

- The acquisition of Whole Foods by Amazon in 2017 added a major player in the grocery industry to Amazon’s portfolio. It allowed it to expand its e-commerce reach into the offline retail space.

Vertical system integration involves combining or merging companies operating at different supply chain stages to gain greater control over the production and distribution process. Here are some real-life examples of vertical system integration:

- The merger of Exxon Corp and Mobil Carpo in 1999 vertically integrated the upstream and downstream operations of the two companies, allowing them to better control the production and distribution of oil and gas.

- The acquisition of Zappos by Amazon in 2009 vertically integrated Zappos’ online shoe retailing business into Amazon’s supply chain, allowing Amazon to expand into the footwear market.

- The acquisition of kFC by Yum! Brands in 1997, which vertically integrated KFC’s fast-food chain operations into Yum!’s broader restaurant franchise network, giving Yum! Greater control over their food products’ production, supply chain, and distribution.

FAQs

When is Horizontal Integration appropriate?

Horizontal integration is appropriate for a company to expand its product offerings into new markets. By integrating with companies in other industries, a company can gain access to new customers and products. Horizontal integration can also help a company become more efficient and competitive by consolidating operations.

What are the steps involved in Horizontal Integration?

The steps that are included

1. Assessing the potential for horizontal integration

2. Deciding which companies to merge with or acquire

3. Negotiating the terms of the merger or acquisition

4. Completing the transaction

5. Integrating the businesses

What are the different types of Vertical Integration?

There are two main types:

1. Backward vertical integration, where a company controls its suppliers

2. Forward vertical integration, where a company handles its distributors or retailers

Define horizontal and vertical integration industry 4.0

Horizontal integration and vertical integration is a term used in business. They refer to when a company buys another company with similar products or customers or adds new capabilities.

In Industry 4.0 and pursuing the smart factory goal, horizontal and vertical integration have different meanings. They center on technologies, processes, and systems that enable data collection, collation, communication, and use.

Conclusion

As we move into the fourth industrial revolution, or Industry 4.0, horizontal and vertical system integration will be essential for businesses to remain competitive.

However, each type of integration has advantages and disadvantages, so it is crucial to consider which is right for your company.

Vertical integration can give you greater control over your supply chain and production process but also requires a significant up-front investment.

On the other hand, horizontal integration can lead to increased market share and economies of scale, but it can also complicate coordination between different parts of the company.

Ultimately, deciding which type of integration to pursue will depend on your company’s goals and needs.