Planned orders are the fundamental building blocks of modern supply chain management, meticulously fine-tuned to synchronize the arrival of goods precisely when needed.

In material requirements planning (MRP), planned order is a process that determines the number of items that need to be ordered to meet the future demand for those items.

It serves as a strategic directive, generated by complex ERP systems, that dictates when and how much of a specific material or product should be ordered to meet anticipated demand.

The planned order quantity is then used to create purchase or manufacturing orders. This helps ensure that the correct quantity and variety of items are always available when needed.

This article discusses planned order and the terms related to it. It also includes details on the role of planned order in MRP, examples, and how it differs from a purchase requisition.

Introduction

It is a suggested production, purchase, or replenishment order generated by MRP or other planning systems to meet a projected shortage against desired safety stock levels.

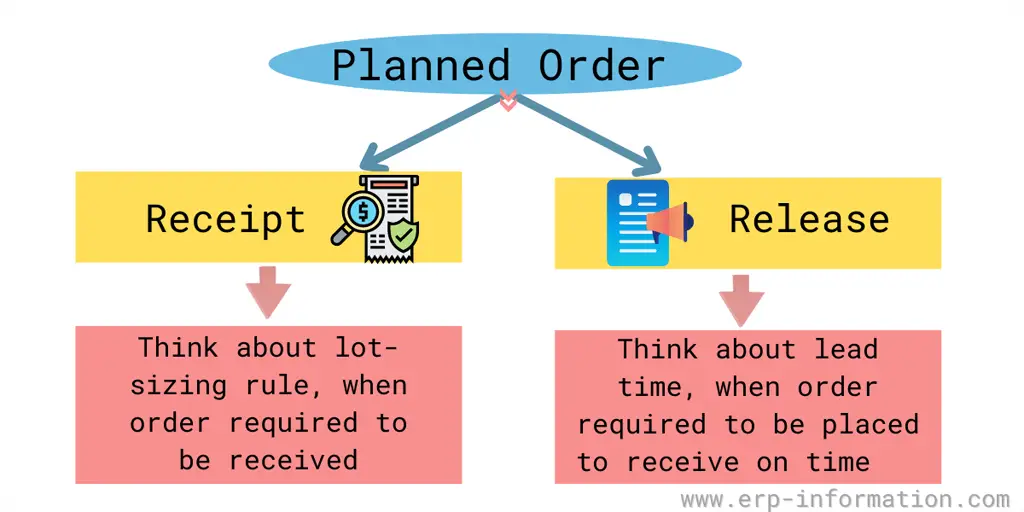

The shortage date becomes the due date, the release date is backward scheduled based on the lead time, and the quantity is based on the specified lot size.

Planned orders for upper-level items create requirements for lower-level components, and MRP generations delete existing planned orders and regenerate new ones based on changes in requirements.

It must be firmed or accepted before being released to production or a vendor.

What is it in detail?

It is a term used in the MRP glossary, reflecting the projected shortage of materials, assemblies, or subassemblies against a safety stock value.

A planned order is an MRP generated for procuring required materials to replenish inventories.

The number of units ordered firmly at the beginning of a productive time fence is known to make up for spent inventories.

It is always well calculated and ordered in specific quantities or lot sizes. When the projected available balance from the previous time fence is zero, after netting the scheduled receipts and inventory from the gross requirement, an MRP is generated for a planned order.

This order is firmed and does not get canceled due to minor changes in the system.

What is the role of a planned order in MRP?

MRP is a computer-based inventory management system developed by a computer engineer to achieve the computerized moderation of the inventory and automation of the manufacturing process.

It makes the manufacturing process more accessible and has assisted production managers in scheduling purchases, keeping a tab on the materials required that are already present in the on-hand inventory, and setting up due dates for that.

Materials requirement planning is an ingenious method to automate the complicated inventory management system and simplifies a detailed procedure of material inflow, maintenance, production purchases, scheduled stocking of the inventory, demands, and products delivered accordingly.

Planned order in SAP

Planned order in SAP is a component of MRP used when the inventory on-hand and scheduled receipts together generate a negative balance after netting from the gross requirement amount.

SAP is an automatically scheduled order for materials at the beginning of every productive time fence only if the system qualifies for it.

MRP is of two types,

- Based on the expenditure within a specific time fence.

- Based on the consumption rate of the past periods.

No other requirement than a specific range of projected available balance can trigger an automated planned order.

In the case of a specific time fence, the available stock or on-hand inventory, along with the scheduled receipts, are considered for calculating whether a planner order release is required or not.

In the case of consumption-based requirement planning, the past expenditure of materials, production costs, on-time deliveries, and customer service level are considered for generating a planned order within a particular time fence.

Example

Let us consider an example.

Suppose an on-hand inventory present at a given moment is 40, and the demand for the first week is 50.

Now, as the demand exceeds the projected balance, the entire balance is used up with ten more units.

That makes the projected available balance for the next week negative (-10). So now, as the projected balance is negative, an MPS is released of 60 units which makes the balance 50. This MPS release is known as a planned order release.

Now, this week, there is a demand for 40 units. That makes the projected available as 15. The projected availability is now positive, so it does not require any MPS to be released.

Hence, MPS is 0. With a zero MPS, the MRP does not release the order and moves into the next time fence.

Creation of Planned Orders in SAP S/4HANA and in IBP

There are two primary ways:

- Manually: You can create a planned order manually, giving you control over its specifics. Once created, these orders are fixed, meaning they will not be altered by subsequent MRP runs, unless specific conditions necessitate changes.

- Automatically: During a material requirements planning (MRP) run, planned orders are automatically generated based on the system’s calculations of required materials and production capacities. This automated generation helps ensure that production aligns with forecasted demand.

IBP

In the SAP Integrated Business Planning(IBP), planned orders are generated through an order-based planning run. This process aligns detailed order creation with strategic business objectives, facilitating more informed and agile decision-making.

How are purchase requisitions different from planned orders?

There is no difference between the planned order and the purchase requisition. A planned order or production order is the predecessor to a purchase requisition.

An adequately investigated and rightly generated planned order later becomes a purchase requisition. This order gives the appropriate controls to a business to make purchases on the grounds of business requirements.

FAQs

What factors influence the creation of planned orders?

They are shaped by various factors, including demand forecasts, lead times, safety stock considerations, production schedules, and supplier performance.

How do planned orders aid in inventory management?

They aid in optimizing inventory levels by facilitating just-in-time procurement, reducing excess stock, and minimizing carrying costs.

What is the role of technology in planned order management?

Modern technology, such as inventory management software and supply chain optimization tools, is integral to the creation, tracking, and optimization of planned orders. These tools employ data analytics and automation to enhance the precision of planning.

What is the significance of safety stock in planned order management?

Safety stock serves as a critical component in this management, acting as a cushion to accommodate demand fluctuations and supply interruptions, thereby preventing stockouts and ensuring operational continuity.

Conclusion

Planned order is a part of MRP. It is used to set up the production plan for raw materials and work-in-process inventory in an assembly line process.

It identifies how many units will be needed at each stage of operation of the manufacturing process and when these items need to be produced.

In other words, given certain input factors such as demand forecasts or availability from suppliers, it’s a schedule of what needs to happen on which day.