In today’s fast-paced and highly competitive market, every industry faces the challenge of delivering top-notch products at the best possible price.

Achieving this feat requires striking a delicate balance between cost efficiency and quality assurance. As a result, many businesses grapple with the complexities of enhancing their product offerings without compromising on affordability.

However, the solution lies in embracing a robust quality engineering process. By integrating this crucial step into their operations, industries can systematically identify, investigate, and rectify issues at every production stage.

It can be the catalyst that propels organizations ahead of their competition and secures their position as industry leaders.

This blog post will delve into what makes up quality engineering, its methods, trends, how it works within various industries, and many more.

What is Quality Engineering?

Quality engineering is a systematic approach to improving the production of goods and services by focusing on quality control, design and development, and testing.

This is a critical part of any product or service development cycle, as it ensures that products are built accurately and reliably to be delivered to customers on time. As such, this has become an integral part of almost every industry today.

- It involves using various techniques and methods to improve the product design to meet customer requirements and expectations while minimizing costs.

- Additionally, It helps ensure that all products are consistently made with high-quality assurance and safety levels throughout their life cycle.

Methods

Quality engineering is a way to make sure things are made correctly. It includes many different types of methods and tools. Some examples are:

- Quality Management System( QMS): Implementing the QMS in manufacturing will help you with quality products.

- Advanced Product Quality Planning(APQP): The application of APQP is another way of quality production.

- Quality Function Deployment(QFD): This is a structure to meet customer requirements. The customer’s want is translated to favorable production to meet their expectations.

- Failure mode and effects analysis: This is a way to check the parts of a system. It looks for possible problems and what might happen if those problems occur.

- Statistical Process Control(SPC): This controls the production process behavior, issues, and discoveries.

- Root Cause Analysis(RCA): Root Cause Analysis helps you to understand why something went wrong. Many businesses and organizations, like factories, hospitals, and airlines, use it.

It involves using deductive reasoning to figure out the cause of a problem.

- Integration with VOC in designing new production

- Interacting with suppliers to get the materials and ensure they are the right size, shape, and quality.

- Necessary tests and inspections to be taken timely

- Waste management by identifying and eliminating

- Interacting with customers to resolve quality issues

Know About Quality Engineers

Quality Engineers are people who work to make sure products and processes are working correctly. They use their knowledge of quality principles to keep things running smoothly.

Some of the responsibilities are listed below:

- Developing, maintaining, and improving the system of process

- They work with the design and manufacturing team to implement the technology for quality production.

- Monitor and control the overall product lifecycle.

- They master defining parameters and crafting end-of-line tests that set the perfect boundaries for outstanding results.

Quality Engineering Trends

User experience

To compete with other businesses, you must put much effort into meeting your customer’s expectations. In the past, customers were willing to settle for whatever product was available, but things have changed.

All products are made according to what customers want.

Engineers need to understand the business, its products or services, and the technologies it uses. Good customer experience depends on how well engineers do their job.

Quality engineering

It is better than testing. Quality assurance is improving and becoming it. This means that tests must be done throughout the business or technology cycle.

In the modern world, customers are directly connected to digital shopping. Customers can try out a product online. The teams can get data from this to help improve the product. Testing helps ensure the product is of good quality and works as it should.

Adaptation of AI, Machine learning, and IoT,

Engineers must become experts to provide good engineering services for businesses using technologies like AI, Machine Learning, and IoT. Engineers must get extra certifications to use these technologies.

Technology brings the world together.

Different industries will start to mix. Ideas from one sector will be used in others. Nowadays, e-commerce, financial services, and the health and insurance industries work together.

Customer expectations can be fulfilled by adopting technologies from one industry to another.

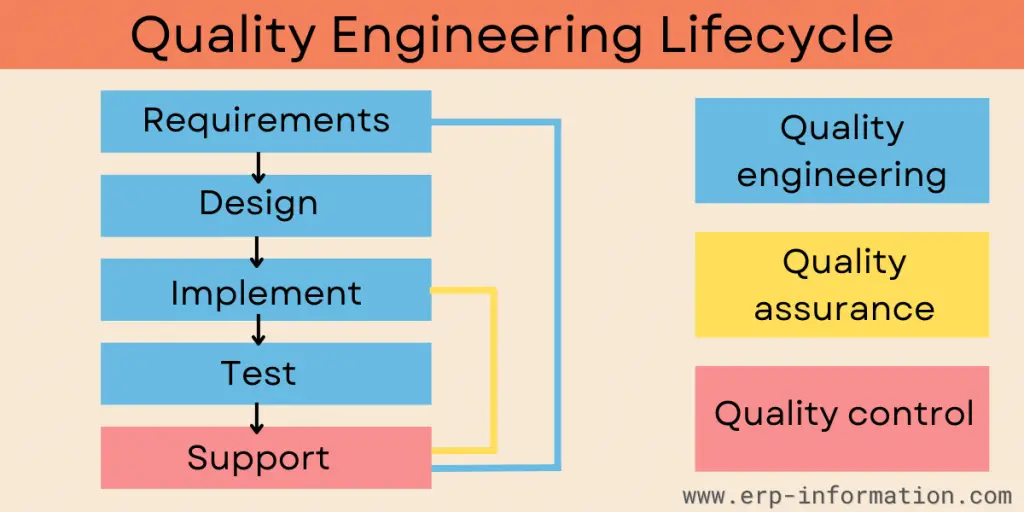

Quality Engineering Lifecycle

It comprises five major stages: planning, design and development, testing, implementation, and maintenance.

Planning

Quality engineers define the product’s desired performance specifications and the production process requirements during the planning stage.

Design

During the design and development phase, engineers create detailed designs for how the product should be built according to those specifications.

Testing

During the testing phase, engineers run tests on prototypes or existing products to identify potential issues or improvements that need to be made before production can begin.

Implementation

During the implementation phase, quality engineers work with production teams to ensure that each step in the production process meets their standards.

Maintenance

Finally, during the maintenance phase, engineers continue conducting tests and monitoring production processes to ensure they remain efficient and effective.

How do quality engineers calculate the quality of a product?

Quality of a product = Result of work efforts / Total costs

Quality Engineering in Various Industries

Many companies need quality assurance engineers. These people help make sure projects are successful. They make sure that all the quality control rules are followed correctly. Industries like

Software

Quality engineers can ensure that software companies use the best practices. This will help their products improve, and the company will make more money. Quality engineers can also help teams automate processes using Artificial Intelligence (AI).

E-commerce

Quality testing in e-commerce platforms ensures everything works correctly. Testing prevents errors and makes the product better. It also helps ensure that the applications work on different phones and computers, no matter what language people speak, and that it looks the same in different web browsers.

Manufacturing

Quality Engineering is when you look at a product’s design, how it was made, and how it is made. It helps make the product better and find things that are wasted.

It helps manufacturer do their job better. This can help them make a good relationship with customers, which will help their business get better and bigger.

Pharmaceuticals

In the pharmaceutical sector, it is important to have good engineering. This is because it helps make sure that the products are high quality.

High-quality products help prevent and treat medical problems. Quality engineers make sure that products meet the standards. As a result, they help prevent and treat medical conditions.

FAQs

What are the aspects of quality?

Quality aspects are Performance, Reliability, Durability, Features, Conformance, Serviceability, Aesthetics, and Perceived Quality.

What are the different roles involved in quality engineering?

The different roles involved in quality engineering are Business architect, IT architect, software quality engineer, requirement engineer, product and test manager, and many more.

Conclusion

Quality engineering is critical for delivering services and products that meet customer needs and expectations. In addition, it helps organizations discover new opportunities, improve operational efficiency and maintain a competitive advantage in the market.

Thus, understanding the core principles of quality engineering and using modern technologies will benefit the organization by providing superior service easily, quickly, and affordably.

We hope this blog post helped you understand the importance, trends, tools, and life cycle of quality engineering.