A Shop Order, often called a work order or production order, is a critical document in manufacturing and other industries that deal with physical products.

It is the guiding compass that authorizes and monitors the creation of components and goods within a workshop. Think of it as the choreographer of the production ballet. But what exactly is a shop order, and how does it work?

It serves as an official instruction that authorizes the commencement of a particular job or task within the production process.

In this article, we will break down the shop order process, explore the essential components of a work order form, and demystify the pivotal role these unassuming documents play in ensuring a seamless journey from raw materials to finished products.

So, let’s take a step-by-step journey into the world of shop orders and uncover their significance in the manufacturing landscape.

Definition

A shop order is a work order used to authorize and track the production of parts and products through the shop. It is the same as the production order.

It includes information about the product to be manufactured, such as the item number, quantity, date needed, priority, and layout. This information helps the shop plan and schedule production.

In addition, it can also be used to track progress and identify any problems that arise during production. As a result, it is an essential tool for managing and controlling the production process.

What is a shop order template?

A shop order template contains the necessary information to create it. That includes the name and contact information of the customer, the name and contact details of the vendor, the item to be produced, the quantity needed, and the due date.

The template may also include special instructions for the production process. Once it is created, it is sent to the vendor.

The vendor then uses it to track the production of the item. The shop order remains in effect until the item is completed and shipped to the customer. At that point, the shop order is closed out.

How does a shop order act as an invoice?

Let us assume that a maintenance company receives a shop order internally through phone or e-mail from the customer.

In this case, the person who does maintenance work for that customer takes a printout of the shop order to take to the working location.

Once he is done with the work or service, the customer checks his work, immediately signs it, and pays for the service.

Suppose the customer cannot pay the amount on the spot. At that time, this shop order converts into an invoice.

Shop order form

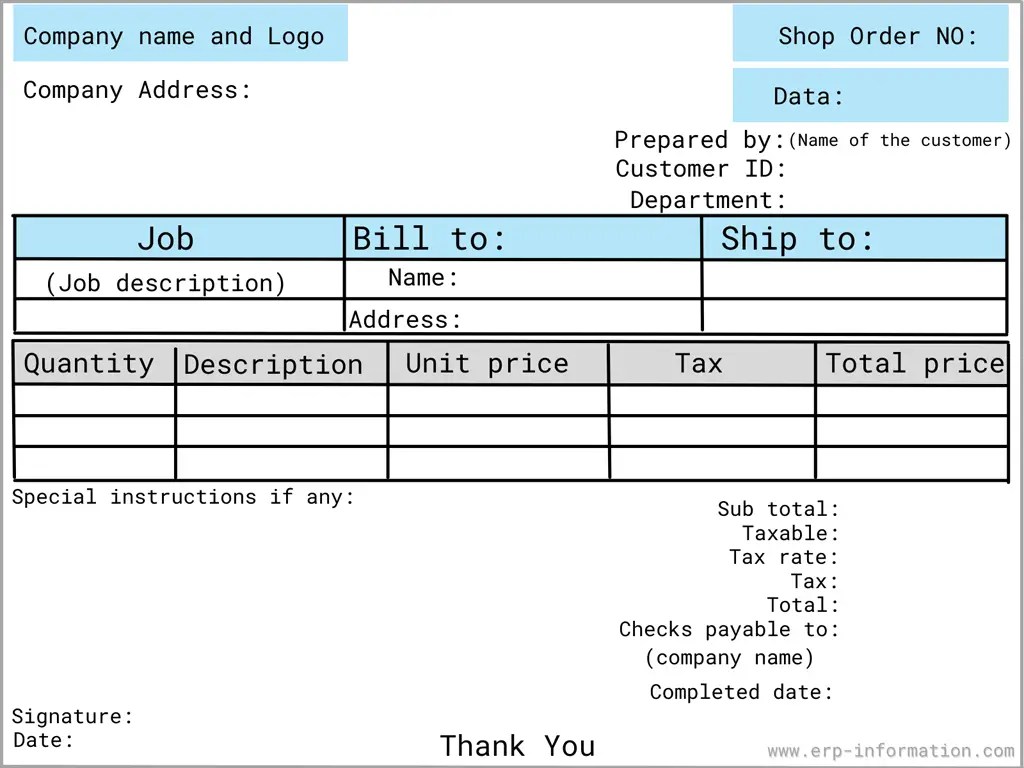

Following is the sample template used to fill out the form.

Typically, each of the forms will have the following fields in them.

- Company name and logo: The company name or logo here will be mentioned. (Logo is optional)

- Shop Order No: It is the unique work order number that helps to identify work.

- Date: It is the issued date of the order

- Job: This field describes the work to be done with complete details.

- Bill to: Name and address of the customer who has to pay the bill for the work done.

- Ship to: Sometimes, the bill to address is different from the shipping address. In that case, the ship-to field indicates the shipping address of the final product.

- Quantity: It is the number of hours spent on the work or the number of products manufactured.

- Taxed: It indicates whether the item or job is taxable or not (in most cases, they are taxed).

- Tax rate: Indicates tax rate for a particular job or product.

- Special instructions: You can mention any special instructions here about discounts or something like that.

Work order meaning

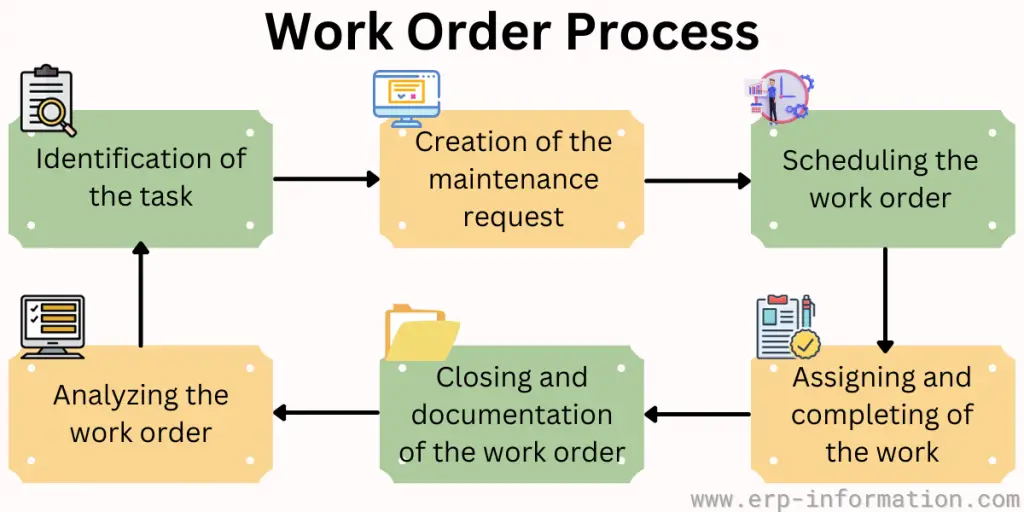

A work order is a document that gives a complete picture of maintenance tasks and outlines the process of completing those tasks.

It contains many details such as the scope of the job, assignee of the job, authorized person of the job, etc.

The customer will issue shop orders to an organization. It can be issued by one department to another department of the organization internally.

It details the products to be purchased or manufactured and the work to be done.

Sometimes, this shop order or work order acts as an invoice.

Conclusion

The shop order is the same as the production order, and it is used to authorize and track the production of parts and products through the shop.

As we explored the journey from start to finish, dissecting the shop order form and how it mirrors an invoice, it became clear that these unassuming documents play an instrumental role in keeping the wheels of the industry turning.

They not only facilitate a smooth and organized production process but also serve as a vital record of work accomplished.

Thanks for reading!