The supply chain execution system is the backbone of any business, ensuring that goods, information, and finances flow seamlessly from point A to point B.

In the contemporary world where immediacy and efficiency are paramount, mastering the art of supply chain execution is no longer a luxury but a necessity for businesses of all sizes.

Whether you’re a seasoned professional looking to understand the dynamics of supply chain management, this post aims to provide valuable insights to help you navigate this complex yet fascinating landscape.

This post discusses the concept of “Supply Chain Execution”. You will learn about its meaning, applications, benefits, challenges, and differences with supply chain planning. The post lists the best Supply Chain Execution software that helps to automate tasks and run the supply chain.

Definition of Supply Chain Execution

It is the process of effectively managing the supply chain. In other words, we can say supply chain execution is the process of providing the supply chain items where they are required most.

It involves the activities related to moving goods and materials from suppliers to customers, including procurement, manufacturing, warehousing, transportation, and fulfillment.

In this digital and technological era, numerous Enterprise Resource Planning Software and Enterprise Application Software are available with an in-built Supply Chain Execution System.

Many large organizations and small businesses are already leveraging these in-built systems to manage their supply chain logistics effectively.

There are numerous tasks that an automated system for supply chain execution can do.

Some well-known software for supply chain execution are transportation management software, warehouse management software, order fulfillment software, and global trade management software.

All of this software, as mentioned above, is geared towards managing the supply chain execution process more conveniently.

For instance, global trade management software allows business owners to manage the transportation and carriage of their products.

Fleet management software enables corporate governors to control the shipment of their finishing goods locally.

Inventory control tools allow a company to save money by achieving a leaner inventory model.

These core technologies and many more may help the company automate the tasks related to Supply Chain Execution.

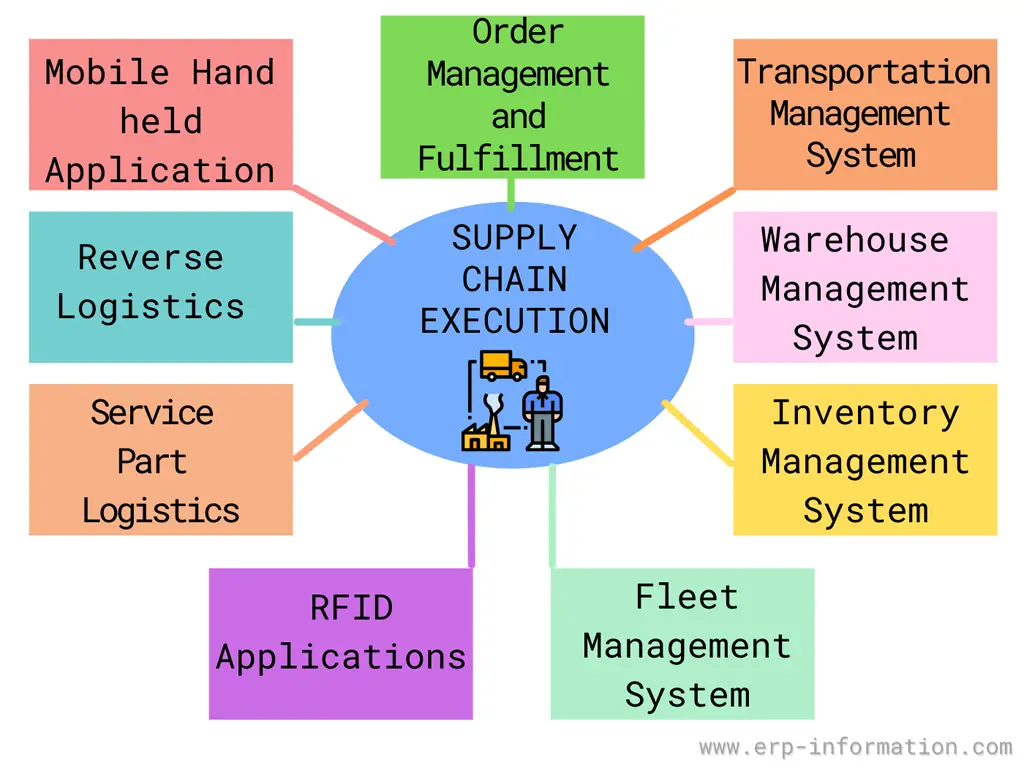

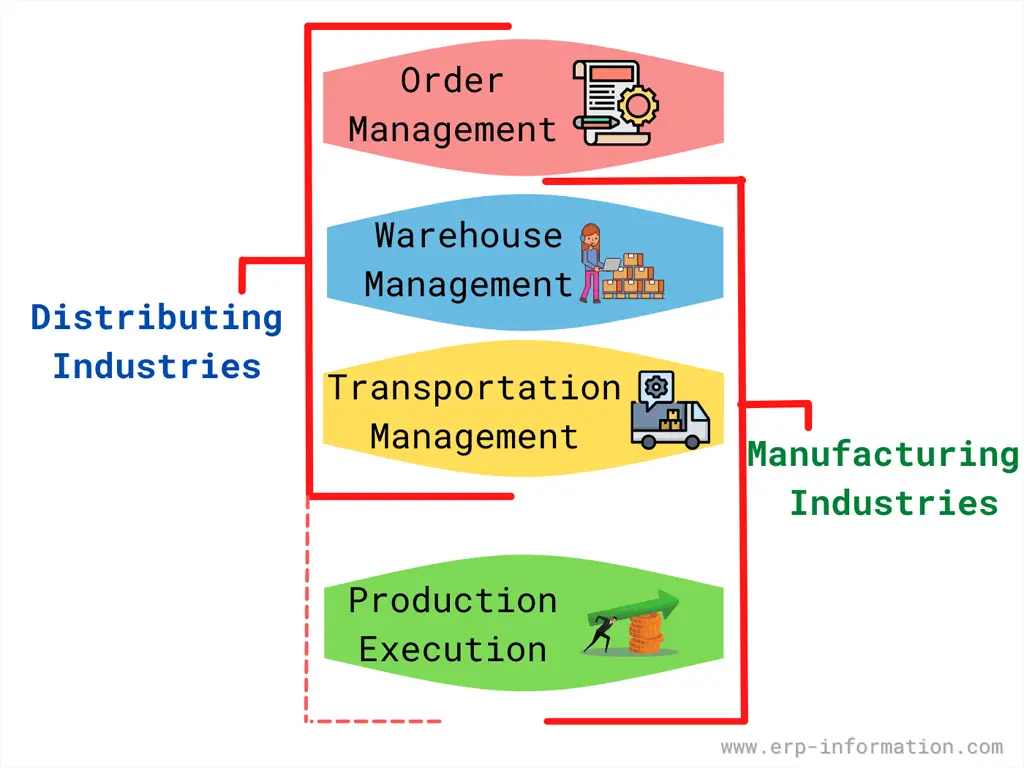

The components that make up a typical SCE system

The main components of an SCE system are order management, inventory management, transportation management, warehouse management, and production planning. Each component is designed to optimize the flow of materials through the supply chain and improve efficiency.

Supply Chain Execution Software

To correctly manage the task related to supply chain execution, we strongly recommend you use the appropriate software. Here is the list of 10 best supply chain execution software.

Top 10 SCE Software Solutions

1. Oracle Transportation Management

Oracle TMS is a cloud-based supply chain management software that offers users a complete view of their transportation operations. It allows users to plan and execute shipments, track shipments in real-time, and optimize routes.

2. Manhattan Associates Warehouse Management

Manhattan WMS is a warehouse management system that helps users increase,

- Productivity

- Accuracy

- Customer satisfaction

- Revenue growth

- Reduce operational costs

3. JDA Manufacturing Planning

JDA Manufacturing Planning is a software application that allows users to plan and optimize production processes. It helps users increase production efficiency, reduce inventory levels, and improve customer satisfaction.

4. Infor LN Distribution

Infor LN Distribution software application is designed to help users manage the distribution process. It allows users to track inventory levels, manage customer orders, and optimize route planning.

5. Kinaxis RapidResponse

Kinaxis RapidResponse is a cloud-based software application that helps users manage the production process. It allows users to plan components that comprise a typical SCE system order management component designed to manage customer orders, track inventory levels, and optimize production processes.

6. IBM Sterling Order Management

IBM Sterling Order Management software application is designed to help users manage customer orders. It allows users to track inventory levels, manage customer accounts, and create sales reports.

7. Epicor Prophet 21

Epicor Prophet 21 software application is designed to help users manage the production process. It provides users with the ability to,

- Schedule production

- Auto-generate purchase orders

- Optimize inventory levels

- Improve customer satisfaction

8. Microsoft Dynamics AX Trade & Logistics

Microsoft Dynamics AX Trade & Logistics software application is designed to help users manage the production process. It allows users to track inventory levels, manage customer accounts, and generate sales reports.

9. NetSuite SuiteLedger

NetSuite‘s SuiteLedger is an accounting software application that allows users to track their financial transactions. It helps users manage their cash flow, create financial reports, and track their spending.

10. Infor CloudSuite

It is a cloud-based software application that offers users a complete view of their transportation operations. It allows users to plan and execute shipments, track shipments in real-time, and optimize routes. In addition, it allows users to manage their financial transactions, create financial reports, and track their spending.

Above here is a list of some of the most popular SCM software applications today. Each software application offers users different features and benefits.

Numerous automated software for the supply chain execution can govern the overall manufacturing operations and supervise distribution processes like receiving and fulfilling orders and order shipment.

Application software for supply chain execution works in synergy to create harmony between manufacturing operations required to design a product usable by the customer.

Supply Chain Execution Applications

Order Management System

It allows businesses to receive, process, and fulfill orders from multiple customers. That includes order creation, prioritization, inventory allocation, shipping scheduling, and returns management.

Transportation Management System

It allows businesses to plan and optimize all modes of transportation routes. It also tracks shipments and manages compliance requirements. That can help businesses to reduce transportation costs and improve delivery times.

Warehouse Management System

It can be used to manage the operations of warehouses and distribution centers. That can include tasks such as receiving and putting away, order picking and packing, and shipping.

Warehouse Control System

It can be used along with the warehouse management system to manage warehouse equipment such as conveyor belts, sorters, and scanners and manage their status and performance.

Slotting Software

The autonomous slotting software algorithm is delicately designed to precisely calculate the fast-moving items by mapping the warehouse, velocity of orders, and order mix.

The information obtained through this automated system is then leveraged to determine where each product should be placed to frame the most effective and prominent picking operation.

For instance, fast movers should be placed at a very optimum distance from the shipping area, and slow movers can be recognized at long distances from the storage place.

Companies should place similar items at an appropriate site to minimize pickup errors.

Yard Management System

Richard Kirker, SAP’s solution owner for warehouse management, expressed the importance of a yard management system in these words,

“Yard management system solely relies on the concept of WMS, and Visibility is the greatest issue.”

The yard management system is a valuable and prominent tool to bridge the warehouse management system and transportation gap.

Business owners can easily leverage information the yard management system revealed to analyze the carrier’s delivery performance.

Labor Management Tool

The warehouse management system governs all manufacturing activities and is an automated tool for labor management to manage workers’ requirements efficiently.

Labor management automated tools precisely monitor the performance of warehouse personnel. Aside from all these specific features, the labor-management tool provides real-time feedback to the management tool.

Automated System for Warehouse Management

Smartly managing the inventories required by the business has a long-term impact on business operations.

Well-known corporate leaders emphasize the importance of effective inventory management in these words,

Keeping too much inventory reduces the liquidity of money. But, on the other hand, too few products mean stocks, which leads to the loss of too much capital investment.

An automated tool for Warehouse Management can benefit the proper management of finishing goods inventory. The automated warehouse management system ensures the right amount of stock available in the right place.

The right place may vary from situation to situation. For example, the right place may be the manufacturing facility, distribution center, warehouse, or anywhere.

The most basic warehouse management system lays the foundation for the day-to-day business activities that are crucial to warehousing, including.

- Receiving of order

- Framing a strategy for the practical completion of the order

- Transporting finishing goods from the manufacturing facility to an appropriate place

- Picking, procurement, and shipping of the order

Feature list

An advanced, fully automated warehouse management system may include,

Consistent Upgradation of Inventory

The automated warehouse management system continually upgrades the inventory and calls for the transportation of the finishing well from the manufacturing facility to the pickup area.

It keeps transporting the inventory so pickers won’t run out of stock.

Capable of Handling Large Quantities of Returns

For the last few years, there has been a drastic increase in online shopping; and there is an increase in customers returning items for various reasons.

The automated warehouse management systems have an in-built feature to deal with many returns.

Cyclic Inventory Counting

Automated WMS generally comes with support for the usual inventory accounting process. However, this pre-defined process involved the most accurate inventory counting systematically.

Coordination with the Production Team

The warehouse management system consistently engages with the production team via a handheld RF device and voice technology.

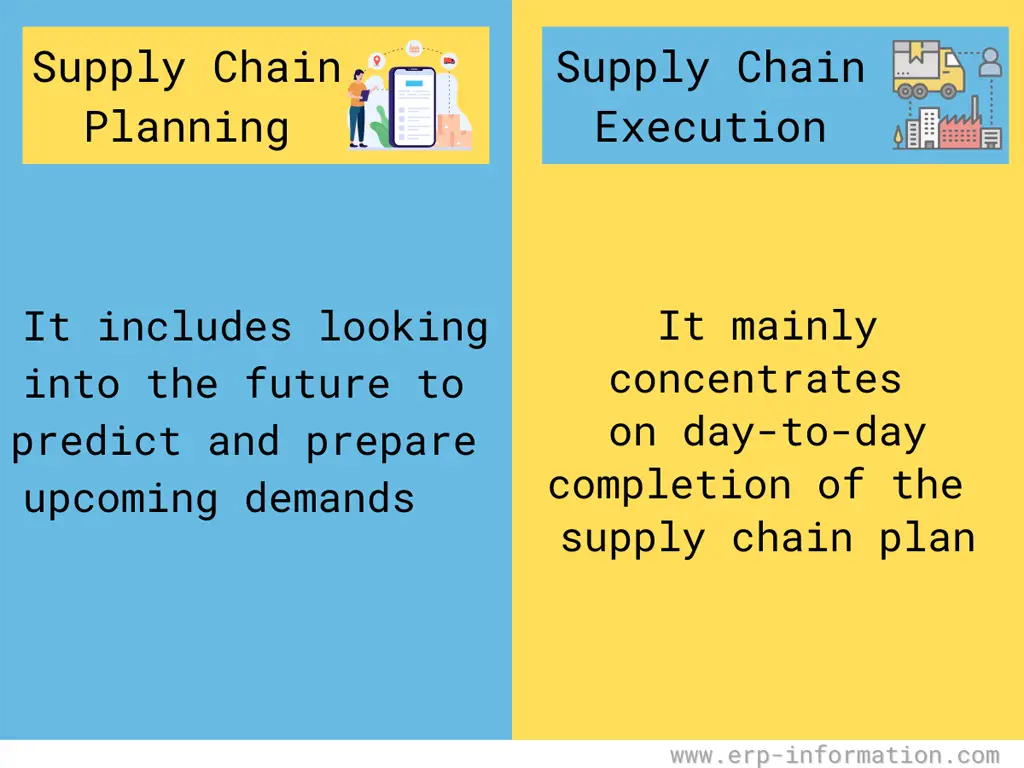

What is Supply Chain Planning?

Supply chain planning helps map the manufacturing process, logistics, and inventory required to meet future demand.

It balances product supply and customer demand by combining pricing strategy, forecasting, and inventory management.

Supply chain planning v/s supply chain execution

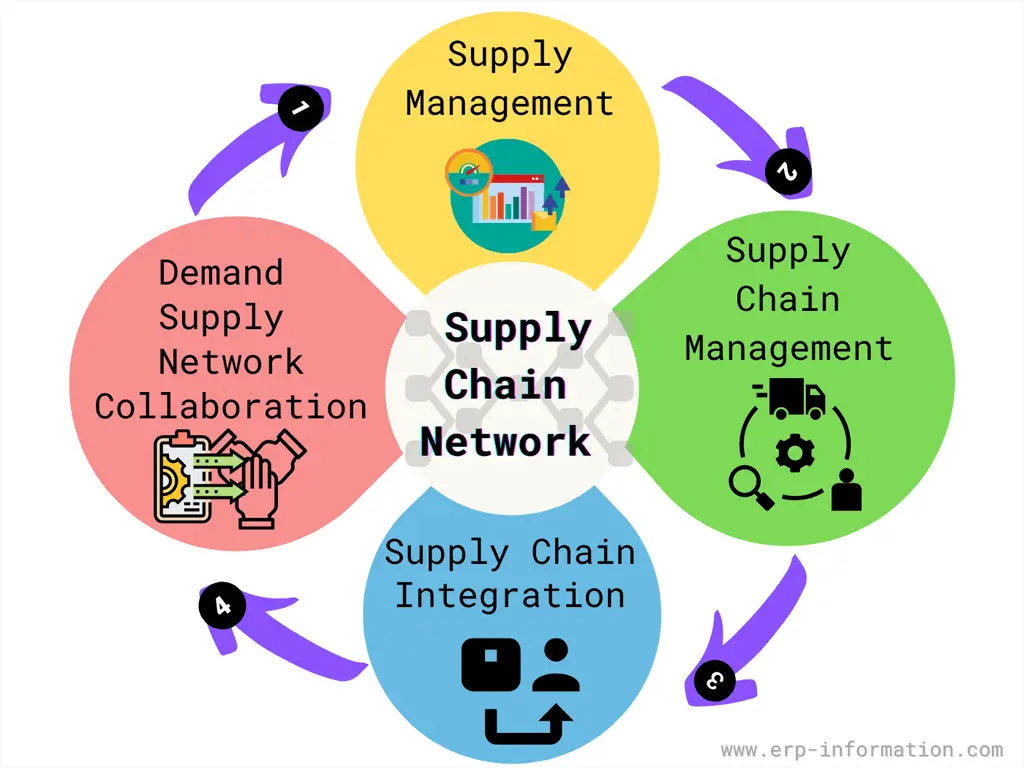

How do you Build a Good Supply Chain Network?

Before executing any work, it is crucial to build the network. Following are the few stages of evaluating a supply chain network.

- The first stage is supply management. It contains tier-one vendors. Interaction with vendors is through documentation like purchase orders and releases.

- The second one is supply chain management. It contains tier-two vendors. Interaction with vendors is through documentation with some data sharing.

- The third one is supply chain integration. It boosts the members in supply to collaborative involvement. At this level, communication will be transactional with the exchange of data and information.

- The last one is demand-supply network collaboration. In this stage, critical information flows through the entire supply chain simultaneously.

Designing the supply chain network

Here are a few tips for building and designing a supply chain network.

- Have a clear idea about your goals: Clearly define the following things.

- The demand for customer service level in the market

- Mode of transportation that should balance cost and performance

- Number of warehouses that you must have

- Amount of inventories that you must have for each product

- Assign a particular warehouse to supply products for a specific customer

- Collect the supporting data: Collect essential data like product demand in the market, transportation cost, inventory, and warehouse cost, lead times during transportation, etc., for a better decision.

- Choose a good tool: It is crucial to have a good supply chain network optimization tool. Choose the tool carefully to address all the decisions you must make and reflect your business.

- Inspect the supply chain network: Keep on analyzing your supply chain network.

- Keep on implementing: It is a never-ending process. So, keep on revising and implementing the supply chain network.

Benefits of Supply Chain Execution

In today’s revolutionary era, supply chain execution has become crucial for companies to remain competitive in an excessively saturated market.

Savvy consumers further intensify the situation as they expect an elegant product from the manufacturers, fast delivery, and a maximum level of accuracy.

An organization can benefit from an advanced supply chain execution system.

Enhance Productivity

Automated tool for supply chain execution generally comes with Radio Frequency picking and voice-activated commands.

The time consumed on manual processes is reduced by one-half through these automated tools.

Productivity is further enhanced by the built-in features of automated supply chain execution explicitly designed to address an organization’s specific needs, such as retail, manufacturing, CPG (example of CPG), and distribution planning.

Optimize Cost and Consolidates Assets

An advanced supply chain execution system appreciates the net worth of an organization’s assets and reduces the production cost across every aspect of the supply chain logistics lifecycle.

With the most potent and elegant tool designed explicitly for streamlining operations, you can efficiently enhance labor productivity, leverage equipment, and improve production capacity.

Sophisticated transportation equipment reduces transportation time and operating expenses. On the other hand, an inventory management system reduces reliance on excess inventory.

Improve the Quality of Manufactured Goods

Small and large-scale organizations and manufacturing firms can enhance the

- Overall order accuracy

- Reduce the cost incurred on an error correction

by the proper implementation of an advanced automated supply chain execution system that includes a computerized system for

- Warehousing

- Transportation

- Billing

Challenges

SCE is a complex and challenging process, and several factors can contribute to these challenges, including:

- Complexity: SCE involves the coordination of many different activities and stakeholders, which can make it difficult to manage and optimize.

- Coordination: One of the biggest challenges is coordinating activities among different players within the supply chain, such as suppliers, manufacturers, distributors, and retailers

- Unpredictability: SCE is often subject to unexpected disruptions, such as natural disasters, political instability, and economic downturns. These disruptions can make it difficult to meet customer demand and maintain profitability.

- Visibility: It can be difficult to track the goods and materials movements throughout the supply chain, making it difficult to identify and address problems.

- Cost: SCE can be a significant expense for businesses, and it is important to find ways to reduce costs without sacrificing efficiency or quality.

Tips to Overcome Challenges

Here are some tips for overcoming the challenges of supply chain execution:

Invest in technology

SCES can help businesses streamline supply chain execution tasks by automating them. That can lead to significant efficiency gains and cost savings.

Develop strong supplier relationships

Strong relationships with suppliers are crucial for a steady supply of goods and materials. Businesses should work with their suppliers to develop joint plans and to identify and mitigate risks.

Improve visibility

Businesses need to be able to track the goods and materials movements throughout the supply chain. SCES can help to improve visibility by providing real-time visibility on inventory levels, order status, and transportation movements.

Build flexibility into the supply chain

The supply chain is constantly changing, so building flexibility into the system is important. That can be done using multiple suppliers, contingency plans, and investing in scalable infrastructure.

Conclusion

In conclusion, the supply chain execution system is an indispensable tool for businesses striving to maintain efficiency and competitiveness in today’s fast-paced market.

It provides a framework for seamlessly transferring goods, information, and finances from origin to destination.

The benefits of implementing a robust SCE system are significant, from cost reduction and increased operational efficiency to improved customer satisfaction.

With many SCE software available, businesses can choose a solution that best fits their needs and objectives.

It’s crucial to remember that while supply chain planning focuses on strategizing and forecasting, supply chain execution is all about action – implementing these plans.

By understanding and leveraging the symbiotic relationship between supply chain planning and execution, businesses can achieve success.