Zone picking is a popular inventory management strategy due to its many benefits. However, like any other inventory management strategy, it isn’t perfect for every business.

Before deciding if zone picking is the right solution for your company, you need to understand what it is and what arrangements are needed for implementation.

This article will discuss the working, pros, and cons of zone picking so that you can make an informed decision. It also informs you about automated order-picking systems and different types of order-picking systems.

Definition and working

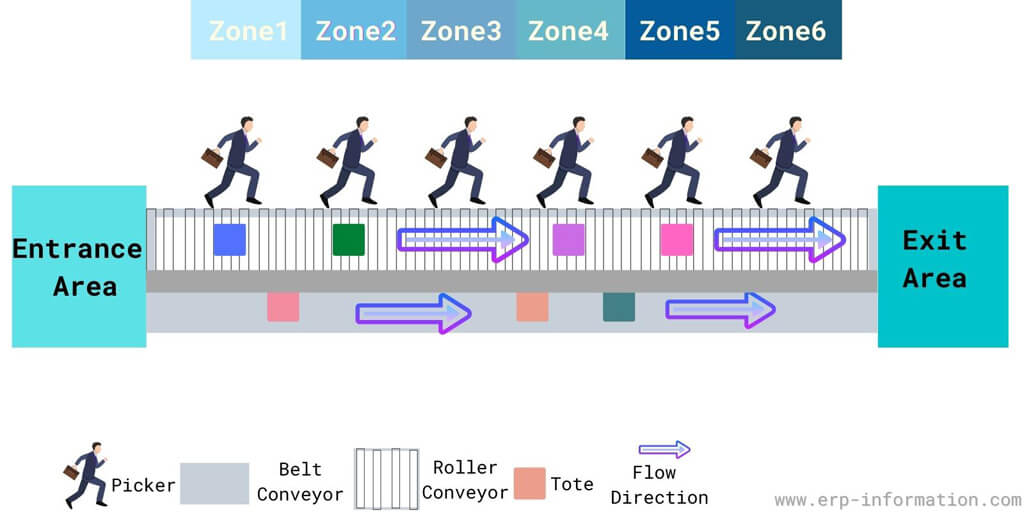

Zone picking is one order picking tool where the warehouse divides into various zones, and products are stocked accordingly.

Each zone is assigned a trained employee who picks up the products as per the order only from their zone.

The products are often collected from various zones to add and collate the goods as required. Products are generally stacked in flow racks or shelves.

The process is generally automated, saving time spent walking and collecting in huge cartons.

It also helps collect goods for several customers in one go, saving time and costs for the business.

It helps in efficient inventory management as the number of transactions recorded will be less and more precise.

Advantages of zone picking

- As each employee is assigned a single zone, they will be familiar with the way goods are stacked. This knowledge will help them pick the goods faster and thus save overall time.

- Once the picker collects the goods from the particular zone, the carton travels to the next zone. This process helps to ensure that the aisles are not blocked, and the collection process becomes swift. In addition, the pickers will be so comfortable with their assigned zones that they might re-arrange their zones, making them easily accessible.

Disadvantages of zone picking

- There are chances that items might get wrongly picked, and since a vast number of pickers are involved, it gets complicated to identify the problem area unless it is brought to the notice of the managers.

- Since pickers can re-arrange the zones, the business structure stacks its goods may alter.

- As it is still a manual process, it requires time and has its own space for errors. It is also tough to assign an equal amount of work to every picker. The reason is that some zones might have a vast demand while some others might not.

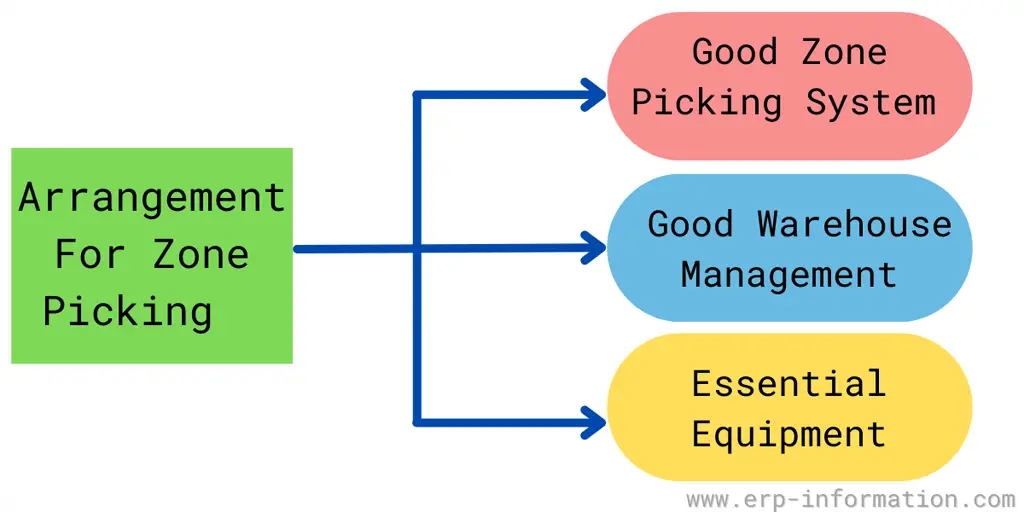

What are the arrangements you need for zone picking?

You need to arrange or organize your warehouse for zone picking. Following are a few tips for managing a warehouse.

Choose an appropriate zone picking system.

There are two types of zone picking systems. Sequential and concurrent. In a sequential zone picking an order moves through all the zones.

For example, an order includes two timers, four tachometers, and five energy meters. Then a person need not go through all the zones to pick the items because all these items are stored in specific areas like

- Zone 1- Timers

- Zone 2- Tachometers

- Zone 3- Energy meters

The order moves through all zones, and employees assigned to the specific zones pick up the items in the order and send them for packing and shipping.

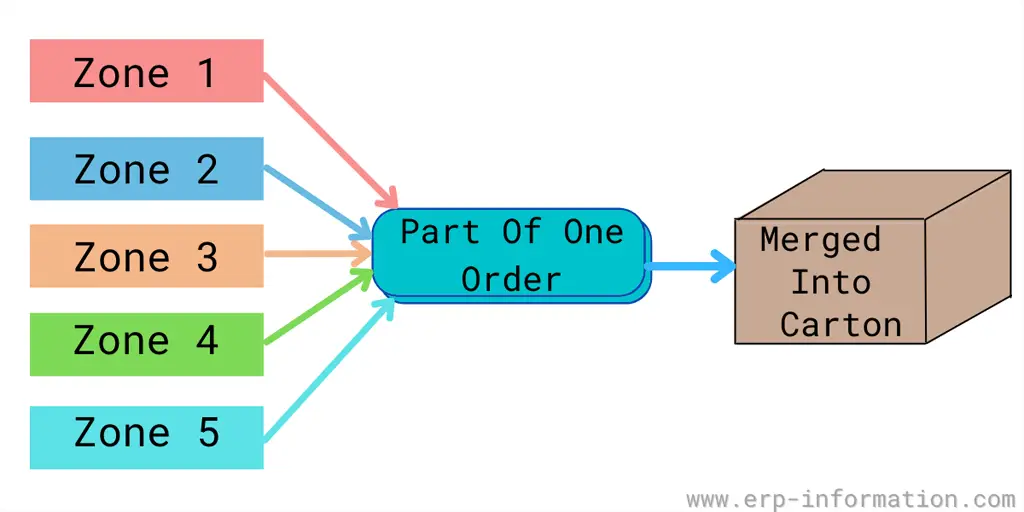

In a concurrent system, the order will be sent to all three zones simultaneously, and each zone picks the specified items and sends them to the parking area for shipping. Then, in the parking area, they are sorted by the order.

Depending on your warehouse nature, you must choose the zone picking system.

Have a sound warehouse management system (WMS)

It is essential to have a warehouse management system with all features. It organizes the process and helps move the orders smoothly through the system.

WMS also helps track the employees by providing specific user IDs so that assigned employees can only carry out the picking process in their given location.

Buy the essential equipment for zone picking.

Equipment and machines help to boost your warehouse zone picking system. Purchase the equipment based on your company’s picking strategy. Three types of strategies are

- Vehicle-based picking strategy

- Conveyor-based picking strategy

- Goods-to-person picking strategy

Wave picking

Wave picking is one more picking method used in the warehouse. In this method, pickers take only one order at a time as per the scheduled orders.

Its advantages are

- It helps to reduce the order-picking time.

- It Boosts the picking and shipping activities.

Its disadvantages are

- It is not possible to perform two waves at a time.

- Pickers have to wait to complete others’ work to start their work.

Automated order-picking systems

Let us glance at the automated order-picking system, apart from the manual.

Following are some regularly used automatic order-picking systems that suites modern warehouses.

- Pick-to-light is a well-automated order-picking system that needs LED lights and barcode scanners on all the shelves in the warehouse. When the bar code of the order scans, LED lights for SKUs of that order switch on, and the picker can easily pick those SKUs.

- In the mobile scanner picking system, all products in the warehouse must have unique bar codes. Picker uses a mobile scanner that shows the list of items to be picked. Then, he scans each item listed. If that item is not listed, then the scanner shows errors.

- In the voice-picking method, the organization’s order management system instructs the pickers about the items to be picked by sending voice instructions through headsets worn by the pickers.

- Mobile robots system is one of the automated methods in that robots are used to assist the picking activities by handling the manual works of product movements.

FAQs

What are the different methods of warehouse order-picking systems?

The different warehouse order-picking systems methods are zone picking, wave picking, batch picking, single order picking, multi-batch order picking, and cluster picking.

Conclusion

As you can see, various methods exist for implementing a zone picking system in your warehouse. Selecting the system that will work best for your specific business and needs is crucial.

With the right equipment and management system, you can smoothly move orders through your warehouse with minimal hassle.

Whether you choose a zone picking system, wave picking, batch picking, or another approach, careful planning and attention to detail are key. Ultimately, the goal of any warehouse order-picking system is to increase efficiency and reduce costs.